What Makes a Snowmobile Shock Absorber Perform in Extreme Winter Terrain

Why Winter Riding Redefines Suspension Design

Snowmobiles push shocks into conditions far harsher than trail bikes or ATVs. Riders face unpredictable snow density, freezing startup, and dynamic weight shifts that challenge rebound and compression cycles in ways dirt and gravel never do.

At -30°C, conventional shock oil thickens, seals contract, and rebound timing slows. On a packed trail, suspension must handle high-speed repetitive compression, while in deep powder it must reset quickly to avoid pack-down. The terrain doesn’t forgive mistakes—poor tuning leads to instability, chassis stress, and rider fatigue.

This is why snowmobile suspension systems demand specialized design, not repurposed off-road shocks.

Cold-Adapted Shock Engineering

Temperature extremes change how every part of a shock works. Bedo designs snowmobile shocks with:

-

Low-temperature damping fluids rated for -40°C, ensuring smooth flow even in morning startups.

-

Cold-tolerant seals and bushings, preventing air leaks during freeze-thaw cycles.

-

Rebound-calibrated valving that recovers fast from deep compressions in powder.

-

Gas pressure tuning that maintains ride height and prevents cavitation under long trail runs.

-

Anti-ice surface coatings that reduce frost buildup on exposed shock shafts.

This ensures ride consistency not just on the first run—but after hours of exposure to freezing wind, moisture, and repeated impact.

Terrain-Specific Demands: Powder vs. Hardpack

Snow isn’t one terrain—it’s many. And shocks must respond differently:

-

Powder conditions require quick rebound to avoid suspension “packing down,” with progressive spring rates to maintain chassis float.

-

Hardpack and icy trails create fast, sharp compressions that need higher damping resistance to protect the chassis and maintain ski stability.

-

Mixed terrain demands adaptable curves, ensuring comfort without sacrificing control.

At Bedo, we validate shocks across classified terrain profiles to ensure one sled can handle all regions—from open groomed trails to steep alpine climbs.

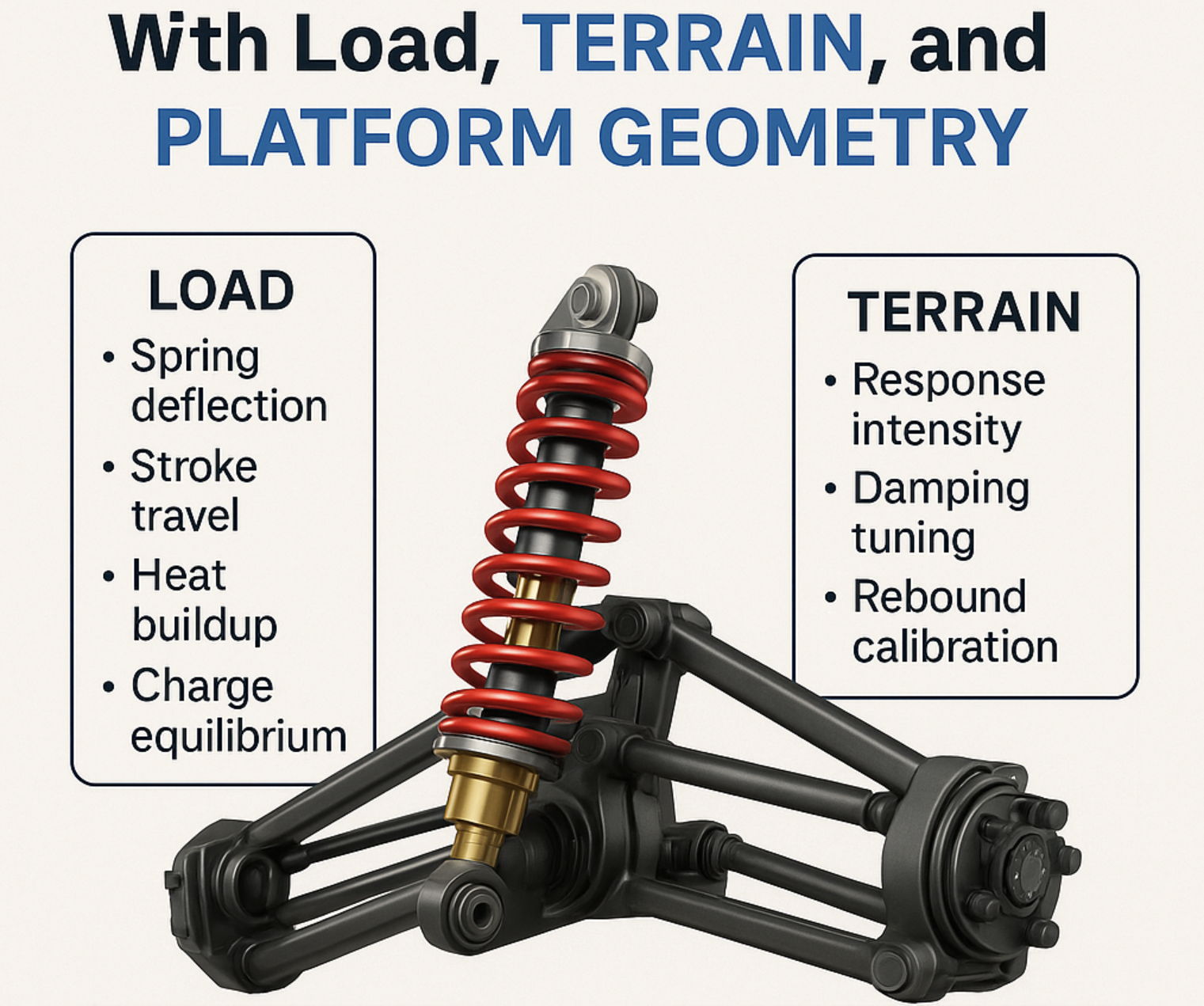

Rider and Load Dynamics on Snow

Unlike ATVs, snowmobiles experience constant weight transfer. Riders lean forward during climbs, shift back on descents, and throw body weight into turns. Cargo racks and two-up seating add even more variability.

A poorly tuned suspension reacts slowly, leading to instability or bottoming. That’s why Bedo develops multi-axis response systems, designed to:

-

Maintain rebound timing under rider lean and roll.

-

Support additional payloads without compromising balance.

-

Keep skis planted for control during side-hill maneuvers.

-

Absorb repeated vertical hits without oil fade.

By treating the suspension as a dynamic system, not a static part, we ensure control across every load condition.

Trail vs. Mountain Shocks: Two Very Different Missions

Even within snowmobiles, suspension requirements differ:

-

Trail sleds demand fade resistance and linear rebound for high-speed comfort on long runs.

-

Mountain sleds require long-travel shocks, rapid rebound, and progressive damping for vertical drops and soft snow landings.

-

Both must integrate seamlessly into the platform’s geometry, ensuring leverage ratios and travel lengths match actual terrain behavior.

Bedo provides platform-specific solutions for both, ensuring OEMs and riders don’t compromise performance by using one-size-fits-all systems.

How Bedo Tests for Real Winter Performance

Design means little without validation. Bedo’s snowmobile shock absorbers go through:

-

Cold chamber dyno testing at sub-zero temperatures.

-

Salt spray and corrosion exposure trials for melt and road chemicals.

-

Field tests across alpine, powder, and trail conditions.

-

Multi-cycle fatigue testing to simulate a full season of riding.

-

Geometry integration checks to ensure platform-specific control.

Every system is validated under conditions harsher than most riders will face—because reliability is non-negotiable.

Smarter Suspension for Snow

Snowmobile riding is unpredictable. Temperatures drop, terrain shifts, loads change—and the suspension must adapt instantly. A true snowmobile shock absorber doesn’t just absorb impacts; it anticipates the extremes of winter riding.

At Bedo, we design systems with:

-

Cold-ready oils and seals

-

Terrain-classified damping curves

-

Geometry-matched rebound logic

-

Durability proven under freeze-thaw and salt spray tests

That’s how we ensure every ride stays stable, safe, and controlled—no matter how brutal the snow conditions get.

Explore Bedo’s winter shock systems for snowmobiles

Contact us for OEM-ready cold-climate suspension solutions