Building Suspension Systems for Desert Racing, Trails, and Utility Buggies

One Platform, Three Very Different Missions

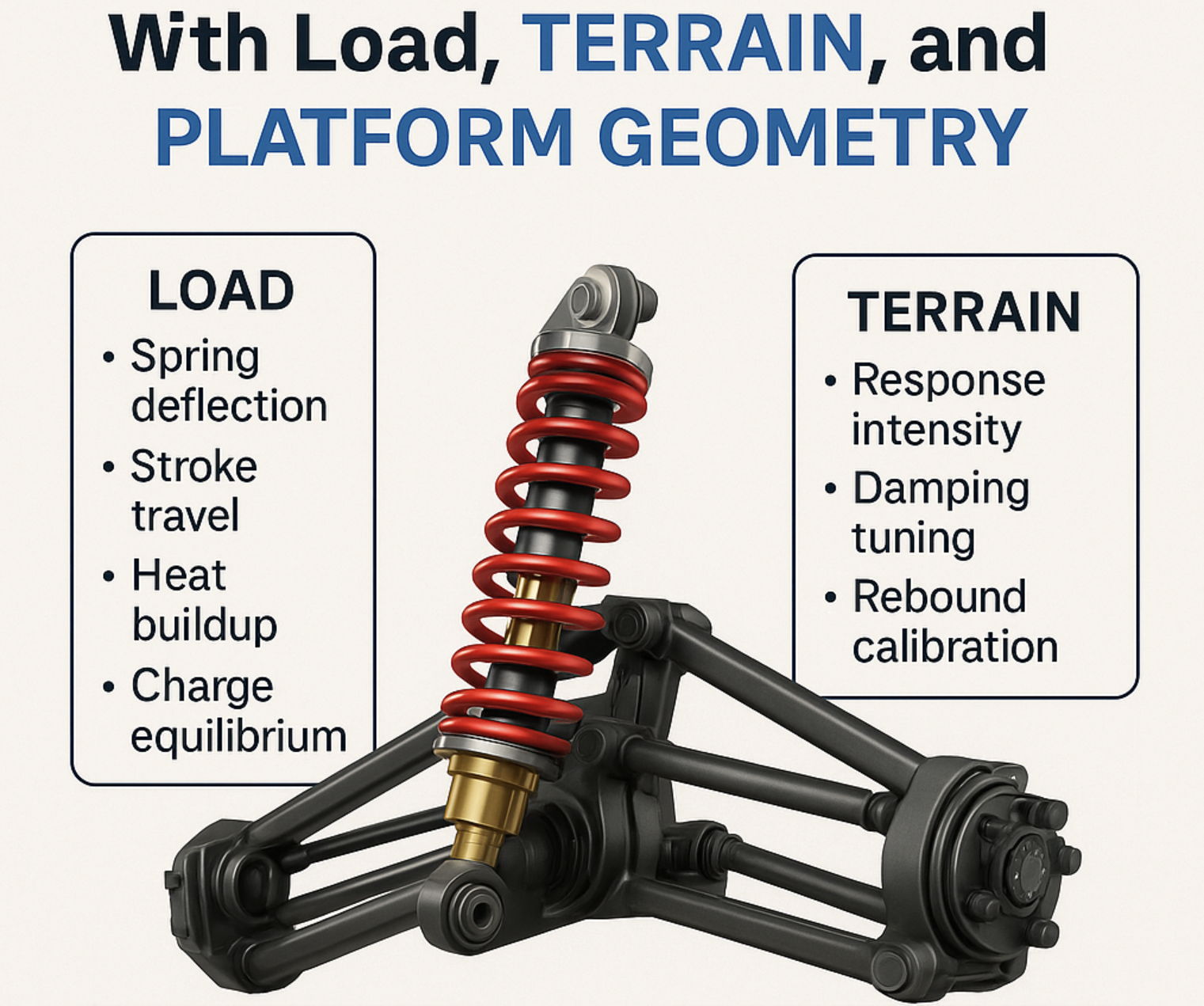

Buggies are versatile machines, but their suspension requirements vary dramatically depending on the application. A desert racing buggy faces high-speed impacts and heat buildup. A trail buggy requires balance between comfort and control. A utility buggy carries heavy payloads and operates in uneven, low-speed terrain.

At Bedo, as a specialized buggy suspension parts factory, we design each system with its mission in mind—because one-size-fits-all suspension doesn’t exist in the real world.

Desert Racing: Precision Under Extreme Stress

Racing environments are brutal. Long-travel shocks cycle thousands of times at high velocity, and temperatures inside the damper can soar. Failures mean lost races and damaged chassis.

Bedo designs desert racing suspension systems with:

-

Large-bore shock absorbers for high oil volume and fade resistance

-

External reservoirs for better cooling

-

Progressive springs that control rebound in uneven terrain

-

Reinforced mounts and bushings to withstand side loads

This ensures consistent damping across long distances and harsh desert conditions.

Trail Riding: Comfort Meets Control

Trail buggies serve a different purpose—exploration and recreation. Riders expect smooth handling over roots, rocks, and mixed surfaces.

For trail-specific suspension, Bedo focuses on:

-

Balanced damping curves that reduce rider fatigue

-

Multi-rate spring setups for comfort and control

-

Noise and vibration control through precision bushings

-

Geometry-aware tuning to maintain chassis stability in tight turns

Our goal is to make trail riding both enjoyable and predictable, without sacrificing durability.

Utility Buggies: Built for Payload and Longevity

Utility platforms aren’t about speed—they’re about work. Carrying tools, cargo, or towing loads places unique strain on suspension parts.

Bedo engineers utility suspension systems with:

-

Heavy-duty coil springs designed for load support

-

Compression tuning to prevent bottoming under cargo

-

Reinforced linkages and hardware for long service life

-

Corrosion-resistant finishes for all-weather operation

These systems prioritize strength, reliability, and serviceability—critical for agricultural, forestry, and industrial use.

How Bedo Integrates Application-Specific Design

What makes Bedo different as a buggy suspension parts factory is our system-level approach. For each application, we integrate:

-

CAD-based geometry simulations

-

Terrain-specific damping validation on dyno rigs

-

Multi-cycle fatigue testing to simulate years of use

-

OEM customization options for platform-specific requirements

By tailoring suspension to its mission, we ensure every buggy performs where it matters most—on the terrain it was built for.

Suspension Built for Every Mission

A suspension system designed for racing won’t suit a trail buggy, and a trail setup won’t survive heavy utility work. True performance comes from understanding the mission first, then engineering the system around it.

At Bedo, we manufacture and validate suspension systems that adapt to terrain, load, and speed—whether it’s a racer in the desert, a family on trails, or a workhorse in the field.

Explore Bedo’s suspension solutions for buggies

Contact us to discuss mission-specific suspension systems