How to Select the Right Factory for Your Custom UTV Coil Spring Needs

From Steel Rods to Springs: Why Factories Define Ride Quality

A custom UTV coil spring is not just a piece of bent steel—it’s the foundation of ride control. Poorly made springs sag, lose rate, or crack under stress, turning suspension into a liability instead of an asset. The factory’s expertise in design, materials, and processes determines whether a spring performs reliably across trails, work sites, and racing tracks.

The Metallurgy That Decides Whether a Spring Lasts or Fails

Coil spring strength begins with metallurgy. Factories using high-alloy steels with advanced heat treatment and shot peening deliver products that resist fatigue and micro-cracks. Without this, springs deform under repeated compression, especially in off-road conditions where shocks face constant load shifts. Buyers should always ask about alloy composition and whether springs undergo stress-relief processes before shipment.

When Millimeters Matter: Precision Manufacturing in Coil Springs

Suspension systems are unforgiving—a few millimeters in pitch or diameter variation can change load behavior dramatically. Factories with CNC winding machines and automated quality checks ensure consistency across every batch. This precision is especially critical for OEM buyers, where thousands of springs must perform identically to maintain platform stability.

Testing Beyond the Lab: How Real-World Loads Expose Weak Springs

Springs don’t just need lab approval—they must prove themselves under terrain-specific stress. Leading factories run:

-

Fatigue cycles beyond 100,000 compressions

-

Load-deflection tests to confirm stiffness accuracy

-

Salt spray trials for corrosion resistance in coastal or winter markets

-

Thermal cycling to simulate hot and cold use cases

If a spring can’t survive these tests, it won’t survive the field.

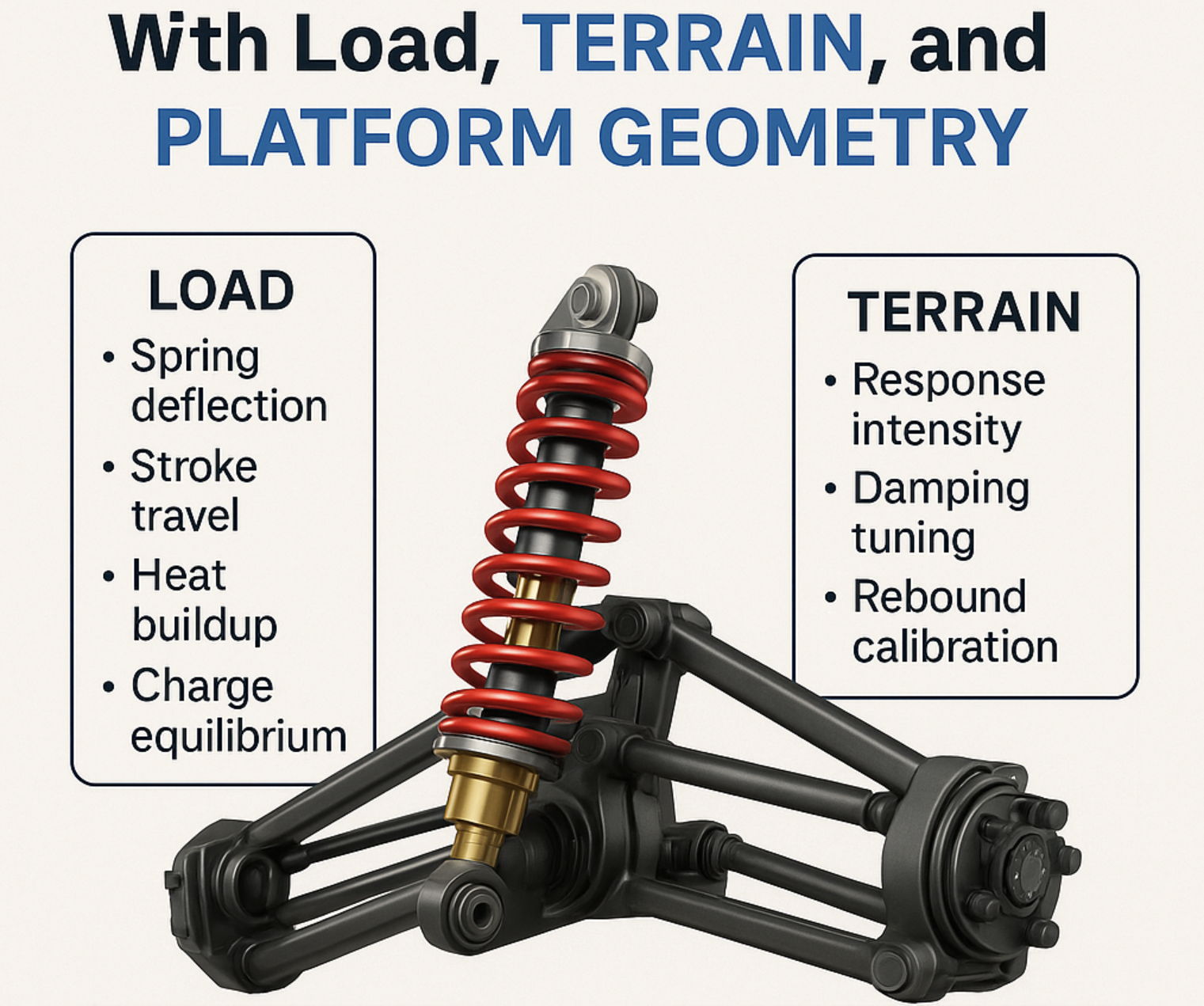

Different UTVs, Different Springs

A work UTV carrying cargo needs a stiffer, load-supporting spring, while a sport UTV benefits from dual-rate or progressive designs for agility. Trail models require comfort-focused tuning. Factories that offer only one “standard” spring simply can’t deliver across all use cases. True customization means engineering coil springs for the mission, not just producing replacements.

Proof on Paper and in Practice: Certifications That Buyers Should Demand

ISO-certified processes, batch traceability, and detailed production records prove whether a factory values long-term quality. For OEM and distributor buyers, this ensures shipments are not only consistent but also auditable. Without certifications, quality becomes a matter of trust rather than proof—a risk few serious buyers can afford.

How Bedo Engineers Springs for Terrain, Load, and Longevity

At Bedo, we combine materials science with platform-specific engineering. Our custom UTV coil springs are:

-

Manufactured from high-grade alloy steels with advanced heat treatment

-

Built using CNC winding and robotic processes for precision

-

Validated through multi-cycle fatigue, corrosion, and thermal tests

-

Customized for utility, trail, and sport UTV platforms

-

Delivered with OEM-ready data and full traceability

This ensures durability, consistency, and confidence in every unit we supply.

Choose Factories That Build Confidence

Coil springs are simple to look at but complex to build right. The wrong supplier means early failures, warranty claims, and disappointed customers. The right suspension parts factory gives you engineering-backed reliability and springs designed for terrain, load, and rider expectations.

At Bedo, we don’t just ship parts—we build confidence. Our custom coil springs deliver precision, endurance, and trust that last far beyond the first ride.

Explore Bedo’s custom coil spring solutions

Contact us for OEM-ready suspension parts