Designing Shock Systems for Multi-Terrain OEM Platforms

One Platform. Multiple Terrains. Multiple Demands.

When OEM teams develop off-road vehicles intended for multiple regions—whether it's Asia, Europe, North America, or LATAM—the product must meet performance expectations across:

-

Muddy, wet forestry roads

-

Dry, rocky highland trails

-

Flat agricultural zones

-

Loose sand and gravel under load

-

Paved transition surfaces

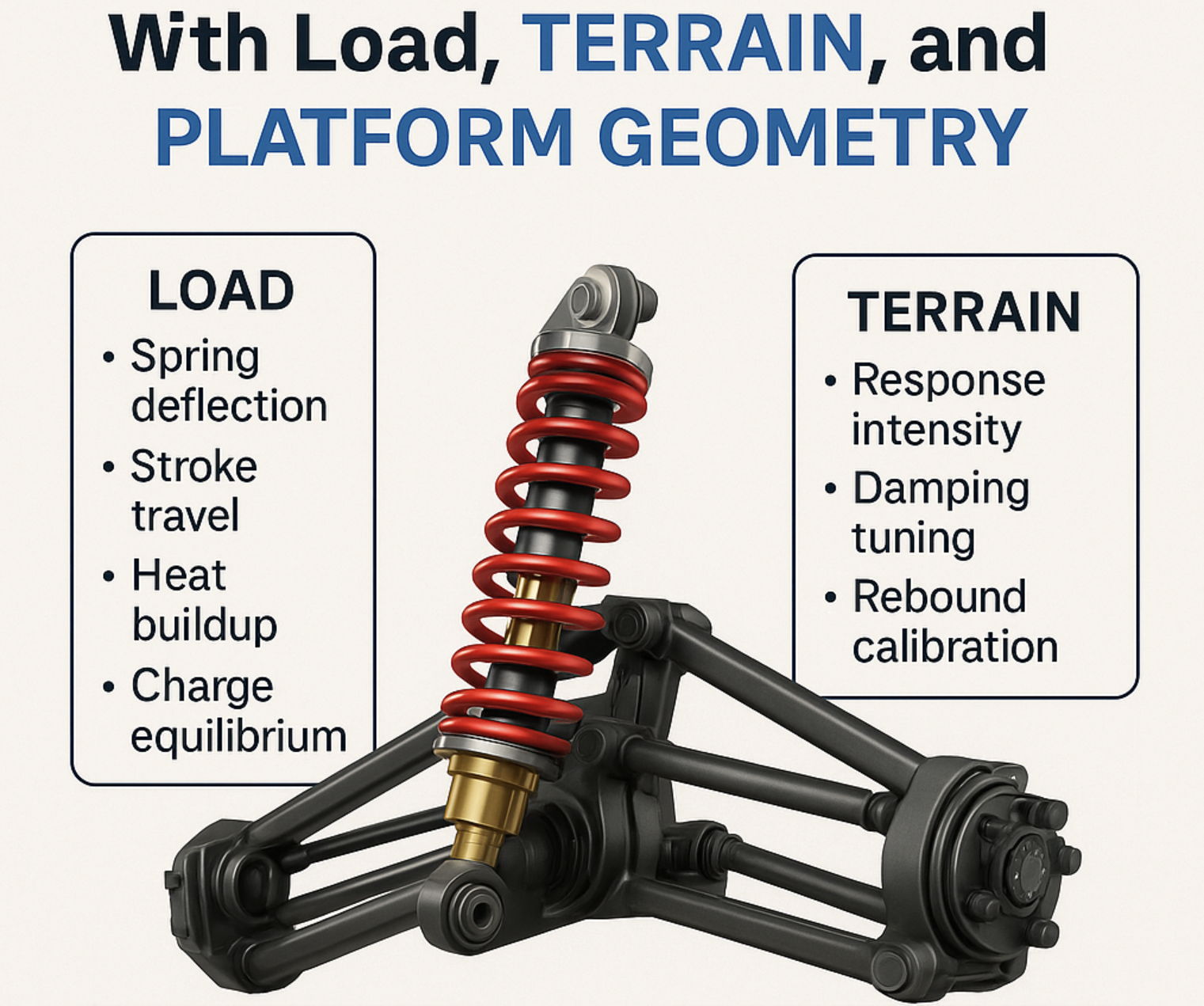

Each terrain places unique damping, rebound, and heat-resistance demands on the shock system.

The challenge? Delivering consistent ride feel and durability—without changing core chassis or components.

Platform-Centric, Terrain-Adaptive Engineering

As a specialized OEM shock supplier, Bedo doesn’t create universal shocks—we build modular, platform-aligned suspension systems that can scale across variant models or terrain targets.

Our method involves:

-

Defining a base shock body with shared geometry

-

Customizing shim stacks and rebound/compression curves for each regional variant

-

Matching spring behavior to expected payload dynamics per market

-

Testing oil and seal durability across ambient temperature ranges

-

Aligning travel limits and bushing specs with platform-level articulation design

This enables consistent manufacturing—but tuned behavior per market.

Why Terrain Profiling Comes Before Manufacturing

Each terrain doesn’t just feel different—it loads the shock differently.

-

Soft soil = higher rebound cycles, lower damping load

-

Rocky terrain = low travel, but high shaft velocity and impact force

-

Long flat distances = heat buildup and potential fade

-

Hilly regions = greater body roll, requiring better rebound control

That’s why Bedo requires OEM partners to share:

-

Terrain usage profiles (from product strategy)

-

Expected ride frequency and max payload

-

Center of gravity and load shift data

We use this to engineer the correct shock response—not just the correct size.

Modular Engineering: Supporting Variants Without Rebuilding Specs

For OEMs with multiple terrain-targeted SKUs, Bedo supports:

-

Shared mounting interfaces across models

-

Interchangeable valve stack design for each region

-

Oil volume adjustments to improve thermal stability

-

External reservoir options for high-performance variants

-

Custom labeling, packaging, and traceability by destination region

This reduces engineering and purchasing complexity—without compromising ride performance.

Testing That Reflects Real Terrain Loads

Bedo's shock validation includes:

-

Multi-terrain simulation cycles on dyno rigs

-

Rebound and compression testing in temperature chambers

-

Field ride tests with OEM project engineers

-

Durability curve mapping by terrain class

-

Response tuning for both rider comfort and chassis safety

Because an OEM shock that survives gravel may still fail under wet mud compression loads—and we test for both.

Building for Terrain Is Building for the Rider

At Bedo, we know OEMs are no longer building just machines—they’re building regional solutions.

Each ride market comes with different expectations, ride habits, and terrain challenges.

Our OEM shock systems are engineered to meet that variability—with:

-

Modular platform tuning

-

Precise damping calibration

-

Durability built into the specification, not just the steel

Let us help you make one platform ride right—everywhere it goes.

Explore Bedo’s multi-terrain OEM shock systems

Speak to our engineering team about your platform needs