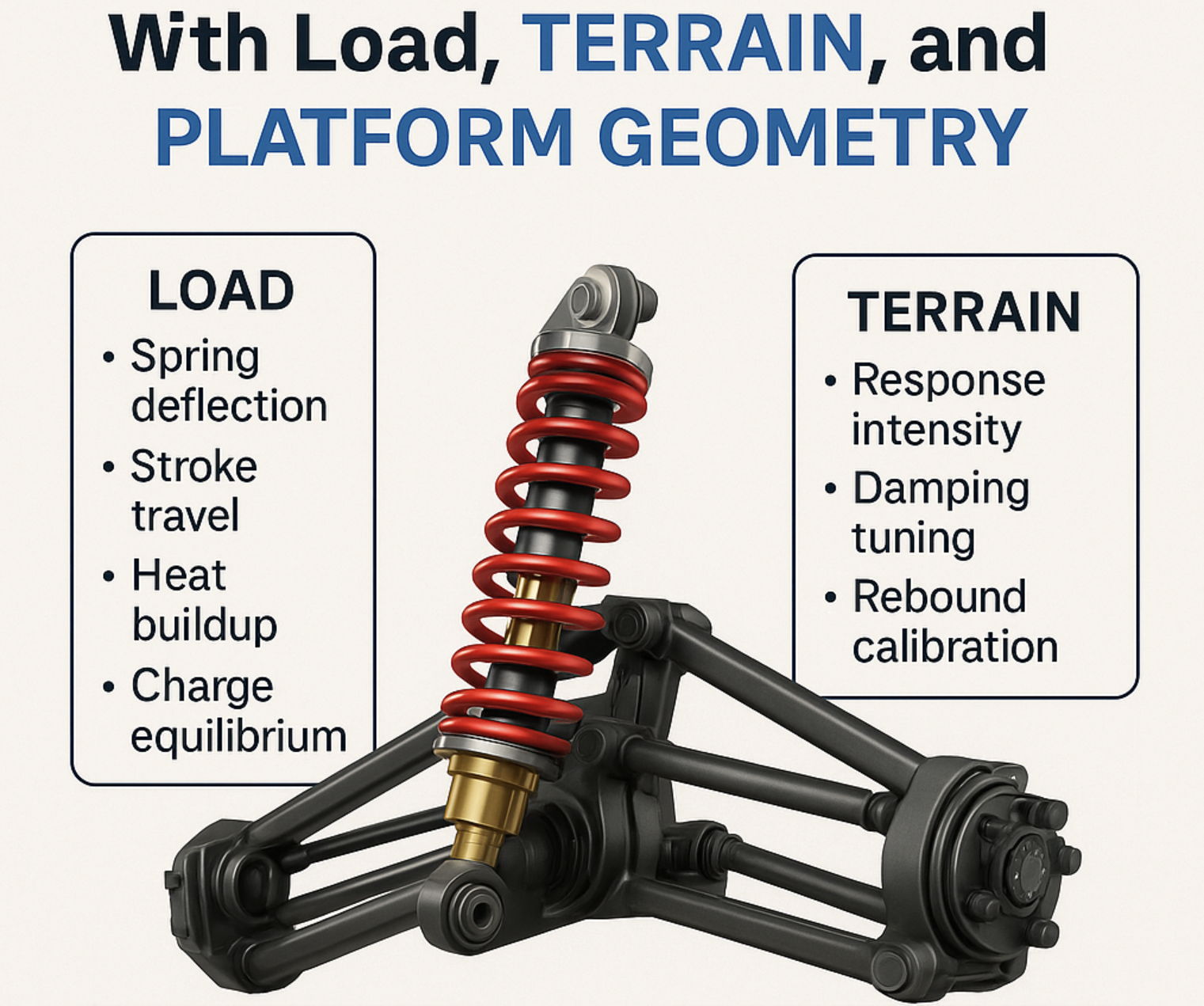

How Suspension Design Changes With Load, Terrain, and Platform Geometry

Why “Fitment” Isn’t Enough

In OEM or aftermarket programs, spec sheets often focus on shock size, travel, and mount compatibility. But experienced platform teams know: fitment is just the start.

Real performance comes from how the suspension behaves under motion, not how it sits at rest.

A true suspension system—especially for multi-terrain ATVs or utility vehicles—must be:

-

Tuned for real load states

-

Designed for terrain-specific cycling patterns

-

Calibrated to platform geometry variables that affect rebound timing and stability

This is the difference between "compatible" and "platform-ready."

Load: The Unseen Force That Changes Everything

A shock system doesn't just support the frame—it absorbs dynamic forces generated by weight under motion. Whether it’s:

-

A loaded cargo rack

-

A passenger seat

-

A trailer under tow

-

Or an on-and-off toolkit setup for utility use

The resulting weight shifts alter:

-

Initial spring deflection (ride height)

-

Compression stroke travel (risk of bottom-out)

-

Oil temperature rise during repetitive damping

-

Nitrogen charge equilibrium over sustained load

At Bedo, we analyze full load variance models and simulate both static + dynamic payload shifts, tuning spring stiffness and damping accordingly.

Our systems are not just built for load—they're built for load variation.

Terrain: Patterns, Not Just Bumps

Terrain changes are not just about how rough the ride looks—they’re about how frequently and intensely the suspension is asked to respond.

Here’s how Bedo interprets terrain into design:

| Terrain | Design Challenge | Our Approach |

|---|---|---|

| Rocky / Gravel | Fast shaft velocity with low travel | High-speed damping tuning and seal durability checks |

| Mud / Soft Soil | Deep slow compression with slow rebound | Emphasis on low-speed rebound calibration |

| Desert / Washboard | Thermal stress from repetition | Larger oil volume and fade-resistant tuning |

| Mixed Utility Use | Uneven daily riding conditions | Progressive dual-rate spring logic |

This is how we create terrain-validated damping response curves—not just general-purpose solutions.

Platform Geometry: The Silent Shaper of Suspension Behavior

Even with identical shocks, different platforms ride differently. Why? Because geometry acts as a force multiplier.

Here’s how:

-

Shock angle alters damping force effectiveness

-

Arm length changes how much leverage compresses the shock

-

Mount offset affects motion symmetry

-

Frame height shifts ride dynamics and sag rate

Bedo uses geometry data directly in our CAD-to-dyno tuning cycle.

We simulate real mounting positions, measure motion ratio effects, and use this data to shape:

-

Damping behavior

-

Rebound delay

-

Spring preload recommendations

This is what allows us to deliver vehicle-specific handling behavior, not just component matching.

How Bedo Integrates These Variables Into Every System

Bedo’s suspension system development pipeline includes:

-

Initial spec alignment with platform teams: payload, terrain profile, shock packaging

-

Spring selection simulation using expected load and travel maps

-

Damping response tuning using terrain-classified velocity cycles

-

Multi-angle dyno testing to reflect platform geometry

-

Field testing under simulated use conditions (wet + dry, hot + cold, loaded + unloaded)

We document all output, from rebound delay vs angle curves to long-term fatigue tests on critical components.

That’s how our systems go from prototype to production—with full terrain + load credibility.

The Right Suspension Isn’t Found—It’s Engineered

Off-the-shelf shocks are easy to find.

But true ride quality—across terrain, under load, in dynamic motion—requires engineering that understands your platform, payload, and purpose.

At Bedo, we don’t build universal suspension—we build application-specific, terrain-tested, geometry-calibrated systems.

Because when the vehicle evolves, so should its suspension.

See Bedo’s suspension solutions by terrain and load class

Discuss your platform's geometry and ride tuning needs