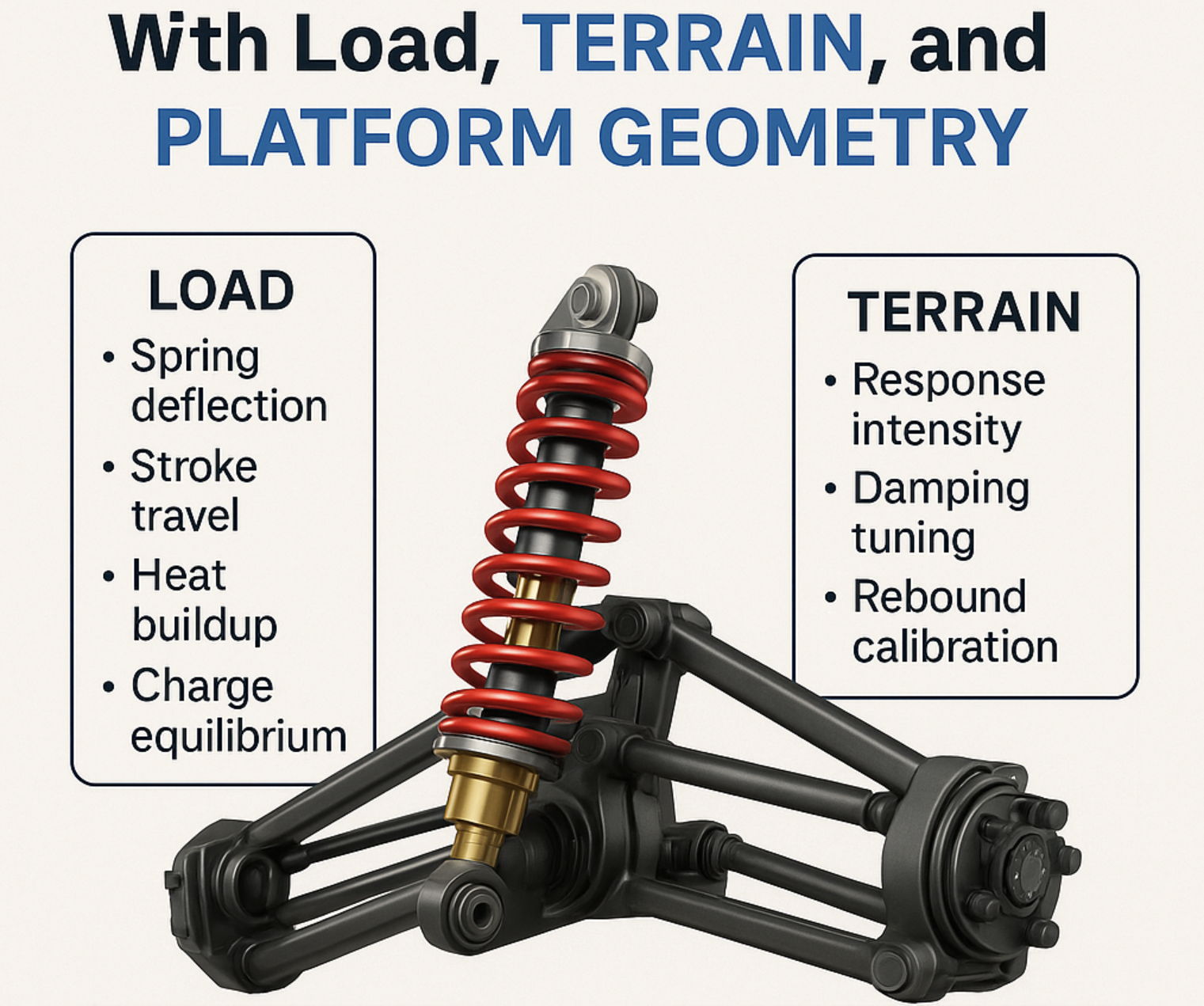

How Suspension Design Changes With Load, Terrain, and Platform Geometry

Suspension Is a Response System—Not Just a Set of Parts

Suspension systems aren’t static—they respond dynamically to what the vehicle is doing. Payload, terrain, and platform design all directly affect how a shock should behave. That’s why top suspension system manufacturers like Bedo don’t just deliver fitment—we deliver performance tuned to real-world variables.

Let’s break down the three forces that shape suspension design more than any part number ever could.

1. Load: The Weight That Alters Everything

Carrying 30kg of tools vs. riding solo isn't just a weight issue—it changes how shocks compress, rebound, and retain heat.

At Bedo, we engineer shock systems that:

-

Include progressive-rate springs for variable payloads

-

Use adjustable preload to compensate for rider + cargo weight

-

Apply rebound tuning to prevent delay under sudden load shift

-

Factor in ride height drop to avoid geometry distortion

This ensures suspension remains responsive—even when your payload doesn’t stay the same.

2. Terrain: Why the Ground Below Dictates What’s Inside the Shock

Gravel roads, forestry tracks, desert washboard, and clay trails all exert different frequencies and forces on your suspension.

We tune:

-

High-speed compression for rocky terrains

-

Low-speed rebound for muddy, soft conditions

-

Oil volume & fade resistance for repetitive flat trails

-

Damping curves specific to each use case, not just a “middle ground”

That’s how we build terrain-calibrated damping profiles—so the suspension responds to ground behavior, not just shock stroke.

3. Platform Geometry: The Silent Variable That Redefines Ride Feel

Even with the same shock spec, two vehicles will behave differently if:

-

Their control arm lengths vary

-

Their shock mount angles differ

-

Their chassis center of gravity shifts with design

That’s why we simulate motion ratios and force paths using CAD and on-vehicle data—ensuring that rebound timing, compression force, and travel limits are matched to the platform, not just the part.

This is how we prevent “wrong feel from the right size.”

What Bedo Builds Differently

As a specialized ATV shock and suspension system manufacturer, Bedo designs around:

-

Load variability

-

Terrain classification

-

Platform geometry simulations

-

OEM ride target data

We don’t build single-performance shocks. We build multi-variable adaptive systems—engineered to feel right, ride right, and last under pressure.

Build for Behavior, Not Just Fit

When designing suspension for real-world applications, fitment is just the starting line.

If your system doesn’t account for how load, terrain, and platform geometry interact under motion, you’re not delivering consistent ride control—you’re leaving it to chance.

At Bedo, we don’t view suspension as an isolated component. We see it as a dynamic response system—engineered to react precisely to every input the vehicle encounters in motion.

That’s why our approach as a suspension system manufacturer focuses on:

-

Load-adaptive damping, not just spring matching

-

Terrain-classified tuning, based on use-case simulation

-

Geometry-integrated development, not just “shock sizing”

-

System durability under fatigue, not just single-pass validation

The result isn’t just a part—it’s a calibrated ride experience tailored to your platform’s mission.

Whether you’re designing a multi-region ATV platform or upgrading your current vehicle’s ride performance, Bedo provides the engineering, testing, and tuning required to deliver confidence over every surface, under every condition.

Explore our ATV-ready, terrain-specific shock systems

Contact us for platform-level suspension design