Spring-Loaded Shock Absorber Specialist: Consistent Control Under Pressure

Unstable Terrain, Predictable Control

Every bump, rut, and incline transfers energy into a vehicle’s suspension. Without precise damping, that energy becomes instability.

Spring-loaded shock absorbers work to absorb these impacts and release energy at a controlled rate, maintaining consistent traction and ride stability. They are essential in off-road vehicles, motorcycles, and industrial machines, where unpredictable ground conditions demand responsive suspension systems.

Specialist manufacturers design these absorbers to withstand intense vibration cycles without fatigue, ensuring smooth rebound and steady compression even under continuous load.

Balancing Spring Tension and Hydraulic Damping

The spring provides the mechanical resistance; the hydraulic chamber manages the rebound. Together, they form a dual-action system that keeps the chassis level and the tires grounded.

A typical spring-loaded damper features:

-

Variable-rate Coil Spring: Adjusts stiffness automatically based on load weight.

-

Oil-Filled Chamber: Converts kinetic energy into heat and dissipates it safely.

-

Piston and Valve System: Regulates compression and rebound speed.

-

Protective Dust Seal: Keeps contaminants out, extending the damper’s service life.

Each element must operate in sync. If spring rate or damping pressure is mismatched, performance declines — especially during sharp turns or rapid deceleration on gravel surfaces.

Comparative Table: Conventional vs. Specialist-Built Absorbers

| Feature | Conventional Model | Specialist-Manufactured Unit |

|---|---|---|

| Material Strength | Mild steel | Heat-treated alloy steel |

| Load Adaptability | Fixed | Variable spring rate |

| Damping Control | Basic valve | Multi-stage hydraulic control |

| Service Life | Shorter, prone to fade | Extended with high-temp oil |

| Custom Fit | Limited models | Tailored per application |

Unlike generic components, specialist-built absorbers are tested to maintain stability across extreme temperature and impact cycles — a crucial advantage for professional off-road and utility applications.

Where Specialized Shock Absorbers Deliver the Difference

-

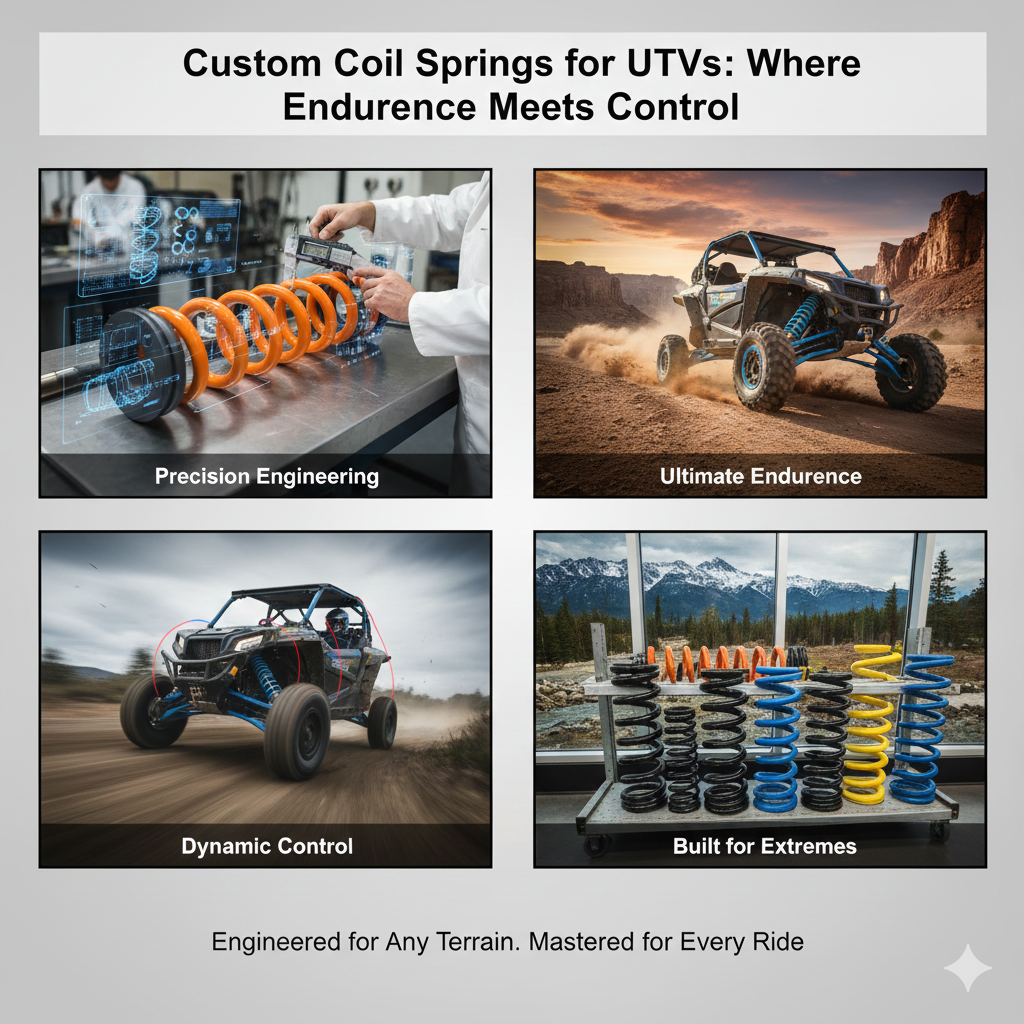

Utility Terrain Vehicles (UTVs): Handle constant load shifts on farm and construction terrain.

-

Adventure Motorcycles: Maintain grip and comfort through long-distance endurance rides.

-

All-Terrain Trucks: Prevent axle hop during heavy towing or steep climbs.

-

Industrial Platforms: Support vibration-sensitive equipment for long operational hours.

In each of these environments, precise spring tuning and controlled rebound separate professional-grade dampers from standard units.

Selecting the Right Spring-Loaded Shock Absorber

Choosing the right absorber involves matching spring constant, oil viscosity, and stroke length to your vehicle’s setup. Consider the following:

-

Vehicle gross weight and cargo distribution.

-

Terrain exposure (rock, sand, mud, or mixed conditions).

-

Expected frequency of high-load cycles.

-

Maintenance capacity and spare part accessibility.

For OEM projects or fleet upgrades, it’s best to consult a certified suspension specialist who can model damping behavior under simulated field conditions before mass production.

Real Buyer Questions Answered

Q1: What makes a specialist spring-loaded shock absorber different from standard models?

Specialist units undergo material heat treatment and pressure-cycle testing to maintain damping performance beyond 200,000 compression strokes.

Q2: Can these absorbers be recharged or serviced?

Yes, most professional-grade dampers include refill ports for nitrogen or oil, enabling long-term maintenance rather than full replacement.

Q3: Do you offer OEM collaboration or customized spring rates?

Yes. Bedo provides custom coil configurations and small-batch production support to match specific UTV, motorcycle, and utility vehicle platforms.

Q4: How are they tested before delivery?

Each absorber passes multi-axis vibration and leak detection tests under ISO-certified processes to ensure safety and stability under real conditions.

Building Reliable Performance with Bedo

Spring-loaded shock absorbers define not just ride comfort but vehicle control and durability.

At Bedo, we combine precise coil manufacturing with advanced hydraulic assembly to deliver consistent, high-tolerance suspension parts for global OEM and aftermarket clients.

Every product is tested for load response, oil temperature stability, and corrosion resistance.

Learn more about our suspension solutions or request a quote via our homepage or contact page.