20 Years of OEM Shock Absorber Expertise: Building Performance You Can Measure

From Early Prototyping to Scalable Global Supply

In the early 2000s, the automotive aftermarket was fragmented — buyers struggled to find suppliers who could deliver stable performance across varied terrains and climates. Over the past two decades, Bedo has evolved from small-batch component production into a fully integrated OEM suspension manufacturer, capable of meeting international testing and customization standards.

Experience matters because it brings repeatable results. Each design iteration has refined the balance between rebound control, ride comfort, and durability — three pillars that define professional-grade shock absorbers for motorcycles, ATVs, and utility vehicles.

How Experience Shapes Manufacturing Quality

Two decades of OEM work means process knowledge is not theoretical — it’s embedded in every line of production.

Key improvements gained through long-term operation include:

-

Material Selection: Use of high-tensile alloy steel and heat-treated rods extends lifecycle under continuous load.

-

Valve Calibration: Decades of test data inform valve tuning for smoother damping across road types.

-

Oil Stability: Proprietary hydraulic fluids maintain viscosity in both high-temperature and sub-zero conditions.

-

Sealing Technology: Custom rubber compounds prevent leakage over prolonged vibration cycles.

This accumulated know-how allows Bedo to maintain less than 0.3% defect rate across thousands of units — a figure verified by OEM audit reports.

Experience vs. New Entrants: What Makes the Difference

| Criteria | Emerging Factories | Experienced OEM Manufacturer |

|---|---|---|

| Production Stability | Batch variation | Process-controlled output |

| Testing Capability | Basic load tests | Multi-axis fatigue & thermal testing |

| Component Sourcing | Third-party vendors | In-house machining & coating |

| Global Compliance | Partial | ISO9001 / IATF16949 certified |

| After-Sales Support | Limited | Lifecycle performance tracking |

In mature OEM projects, reliability is built over time — not claimed through marketing. Twenty years of repetition, refinement, and failure analysis enable systems that scale without compromising quality.

Applications That Prove the Value of Experience

-

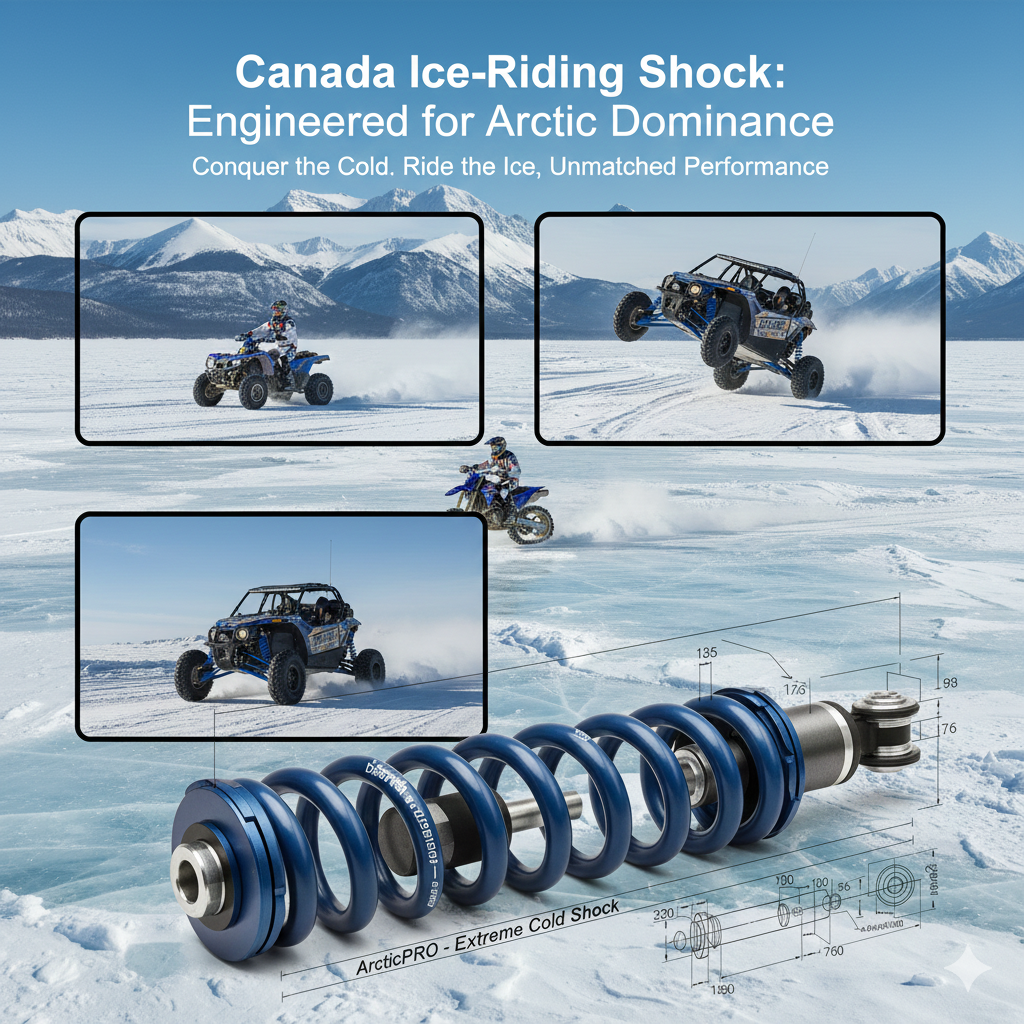

Off-Road and ATV Platforms: Optimized for impact absorption under variable compression loads.

-

Motorcycles: Balanced rebound for comfort and control on uneven roads.

-

Industrial Mobility Vehicles: Reinforced seals and heavy-duty coils for sustained vibration resistance.

-

Electric Utility Vehicles: Lightweight aluminum casings reduce mass without reducing damping stability.

Each market segment benefits from an R&D library built over thousands of test hours — ensuring that every new project starts with verified performance baselines.

Procurement Guidance: What Long-Term Partners Look For

When selecting an OEM shock absorber supplier, experienced buyers prioritize:

-

Traceable Process Control: Documentation for every production batch.

-

Test Bench Verification: Rebound and compression data correlated to design targets.

-

Customization Capacity: Ability to modify stroke length, mounting type, or spring rate.

-

Sustainability of Supply: Multi-line redundancy ensures continuity during peak demand.

A supplier with long operational history reduces risk, simplifies qualification, and supports new model launches with minimal learning curve.

Real Questions from Long-Term Clients

Q1: How does Bedo maintain product consistency across global markets?

By using standardized material grades and automated calibration equipment, ensuring identical damping curves regardless of destination climate.

Q2: What’s the benefit of choosing an OEM partner with 20 years of experience?

Decades of testing data shorten your development cycle — what once required six months of adjustment can now be validated in half the time.

Q3: Can Bedo handle mixed production runs?

Yes. Flexible batch control supports small prototype orders and mass production within the same system, ensuring consistent performance metrics.

Q4: What certifications guarantee reliability?

All lines comply with ISO9001, IATF16949, and RoHS, covering both quality management and environmental compliance.

Experience That Extends Beyond the Factory

Twenty years in OEM manufacturing means more than production — it’s about predictable quality, transparent communication, and continuous improvement.

At Bedo, every shock absorber is tested under real-world load profiles before shipment, ensuring customers receive components that perform as designed, cycle after cycle.

Learn more about our OEM manufacturing capabilities or request a project consultation through our homepage or contact page.