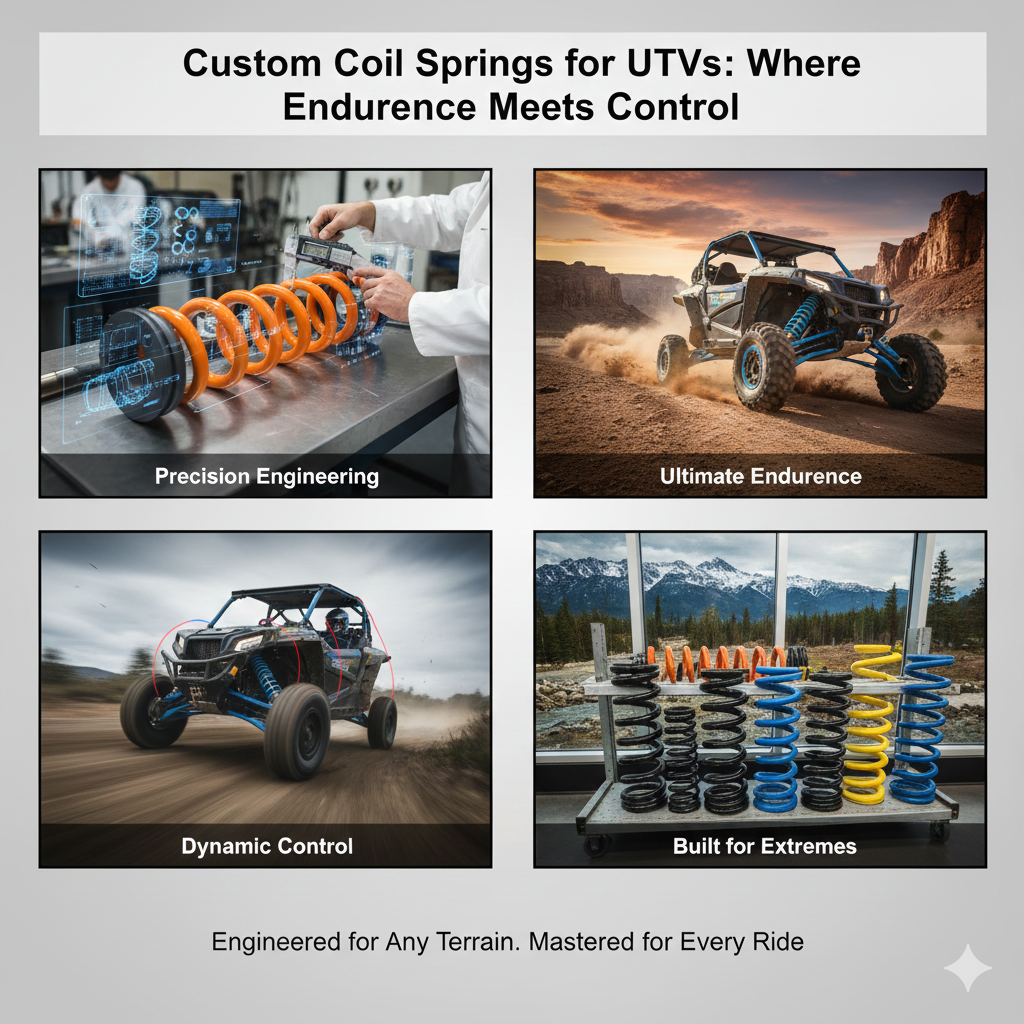

Custom Coil Springs for UTVs: Where Endurance Meets Control

Uneven Trails, Uneven Challenges

UTVs navigate unpredictable landscapes — loose gravel, shifting mud, steep slopes. Standard factory springs often fail to maintain consistent balance under these mixed conditions. As a result, drivers experience instability, uneven traction, and premature suspension wear.

Custom coil springs address these issues by precisely matching the vehicle’s weight, center of gravity, and intended load pattern, ensuring consistent performance across every terrain.

How Custom Springs Improve Off-Road Handling

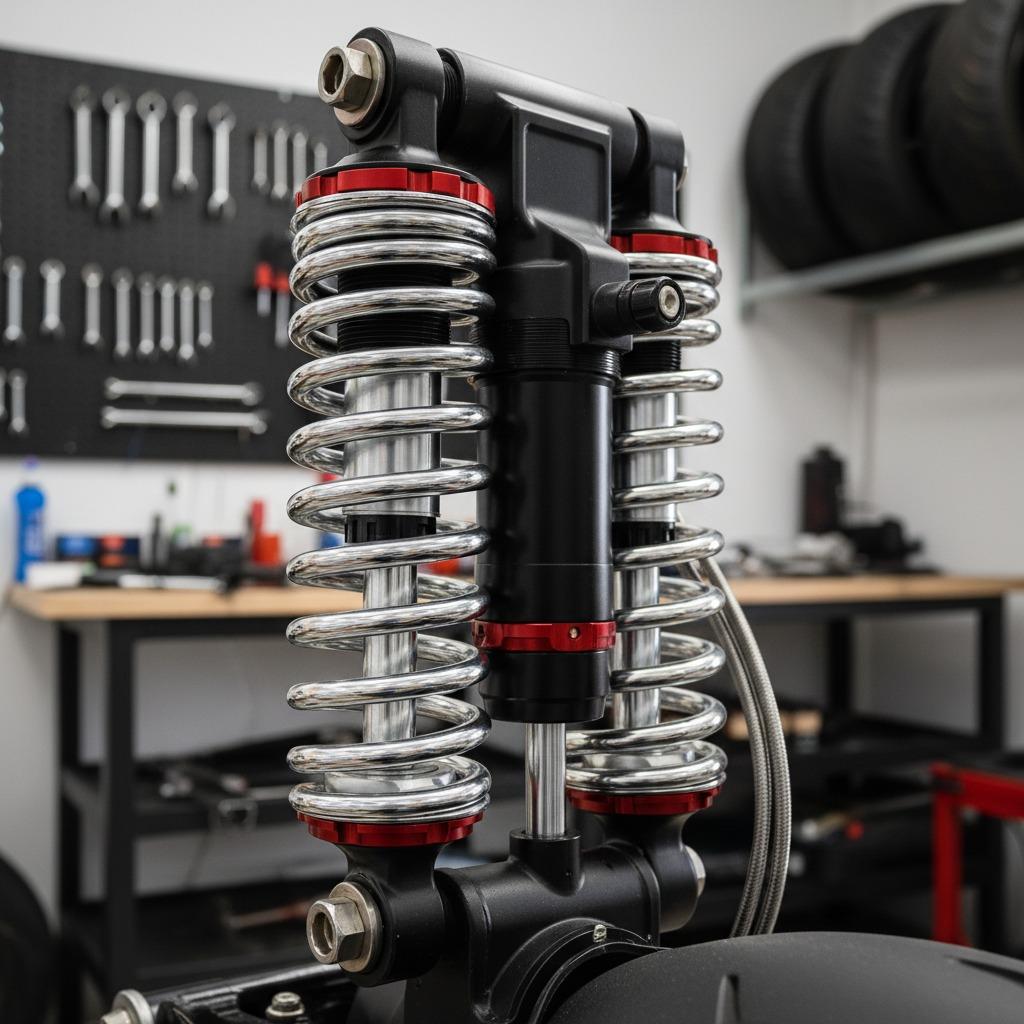

The science behind a well-made coil spring lies in controlled flex and rebound timing. For UTVs, every curve of the wire and every millimeter of pitch spacing matters.

Key aspects include:

-

Material Consistency: High-tensile alloy steel resists fatigue even under high compression rates.

-

Progressive Rate Design: Gradually increases stiffness with load, keeping comfort on light rides while supporting cargo or passengers under full load.

-

Surface Treatment: Powder coating and shot peening extend lifespan by preventing corrosion and micro-cracks.

Together, these factors transform handling precision and reduce vibration across rough terrain.

Comparing Factory vs. Custom Coil Springs

| Feature | Factory Springs | Custom Coil Springs |

|---|---|---|

| Spring Rate | Fixed | Tuned to load & rider profile |

| Durability | Moderate | Extended by heat treatment & coating |

| Ride Comfort | Generic balance | Optimized for terrain type |

| Cost Over Time | Higher due to replacements | Lower through longer life cycle |

| Application | One-fit-for-all | Matched to specific UTV model |

Unlike general-purpose factory sets, custom coil springs are calibrated for actual field use — from farm utility to trail adventure — providing measurable gains in traction and longevity.

Applications That Demand Customization

-

Agricultural Utility UTVs: Heavy cargo loading requires dual-rate coils to prevent sagging.

-

Sport and Trail Models: Progressive coils enhance rebound control and minimize body roll.

-

Fleet & Rental Units: Reinforced springs sustain high usage frequency with minimal maintenance.

-

Winter or Desert Operations: Custom wire diameters adapt to extreme temperature ranges.

By aligning coil configuration with operating context, manufacturers achieve both durability and predictable handling, a crucial factor for professional or commercial UTV applications.

Purchasing Guidance: Matching Coil Design to Real-World Needs

Selecting the right coil spring depends on vehicle weight, shock absorber pairing, and terrain profile.

Buyers should:

-

Identify standard load distribution (single rider / dual / cargo).

-

Choose between linear, dual-rate, or progressive coils based on response preference.

-

Confirm compatibility with current suspension brackets and damper stroke length.

-

Request dynamic testing data from the manufacturer to verify compression-rebound consistency.

A professional supplier can provide tuning assistance and data sheets for each model configuration.

Expert Q&A: What Buyers Often Ask

Q1: Can I install custom coil springs without replacing shocks?

Yes. Many UTVs allow coil replacements independently, but pairing with properly rated dampers delivers the best ride balance.

Q2: How do these springs handle heavy payloads?

Custom coils can be designed with thicker wire or multi-rate segments to manage high loads without bottoming out.

Q3: What’s the expected lifespan?

Under normal off-road use, treated coil springs maintain integrity for 3–5 years, depending on climate and load intensity.

Q4: Do you provide sample production or small-batch orders?

Yes, Bedo supports low-MOQ customization for testing and regional distribution, ensuring reliable validation before scaling.

Building Reliable Suspension Solutions Together

Custom coil springs are not just about ride comfort — they define vehicle capability and service life.

At Bedo, we specialize in designing and manufacturing suspension components that adapt to the real demands of off-road environments.

Each spring undergoes strict ISO-certified testing for compression endurance and corrosion resistance.

To learn more or request tailored solutions for your UTV project, visit our homepage or reach out via our contact page.