Suspension Parts Manufacturer: Building Reliable Ride Dynamics for Global Markets

Why Suspension Quality Defines Every Vehicle Experience

Every movement a rider or driver feels—every turn, bump, or brake—is filtered through the suspension system.

It determines stability, comfort, and safety. Yet many still underestimate the complexity behind these components.

A professional suspension parts manufacturer doesn’t just produce metal assemblies; it engineers energy transfer systems capable of maintaining traction, absorbing vibration, and preventing frame stress over years of operation.

The challenge lies in consistency—producing thousands of identical units that perform flawlessly under heat, vibration, and heavy load.

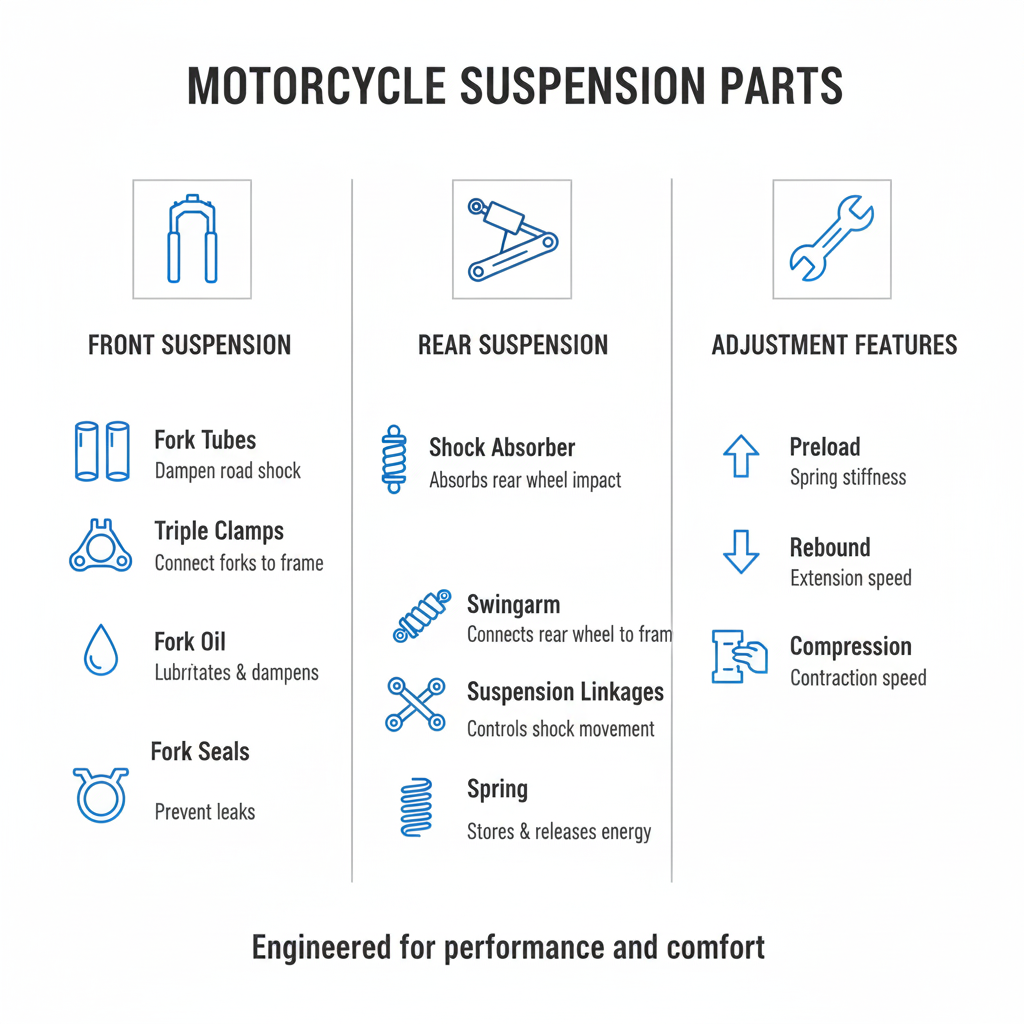

How Suspension Parts Work Together

A complete suspension assembly is a combination of multiple precision parts working in harmony.

Each one contributes to a specific function:

-

Shock Absorbers: Regulate vertical movement and reduce oscillations.

-

Coil Springs: Maintain ride height and load balance.

-

Bushings and Mounts: Dampen metal-to-metal contact and noise.

-

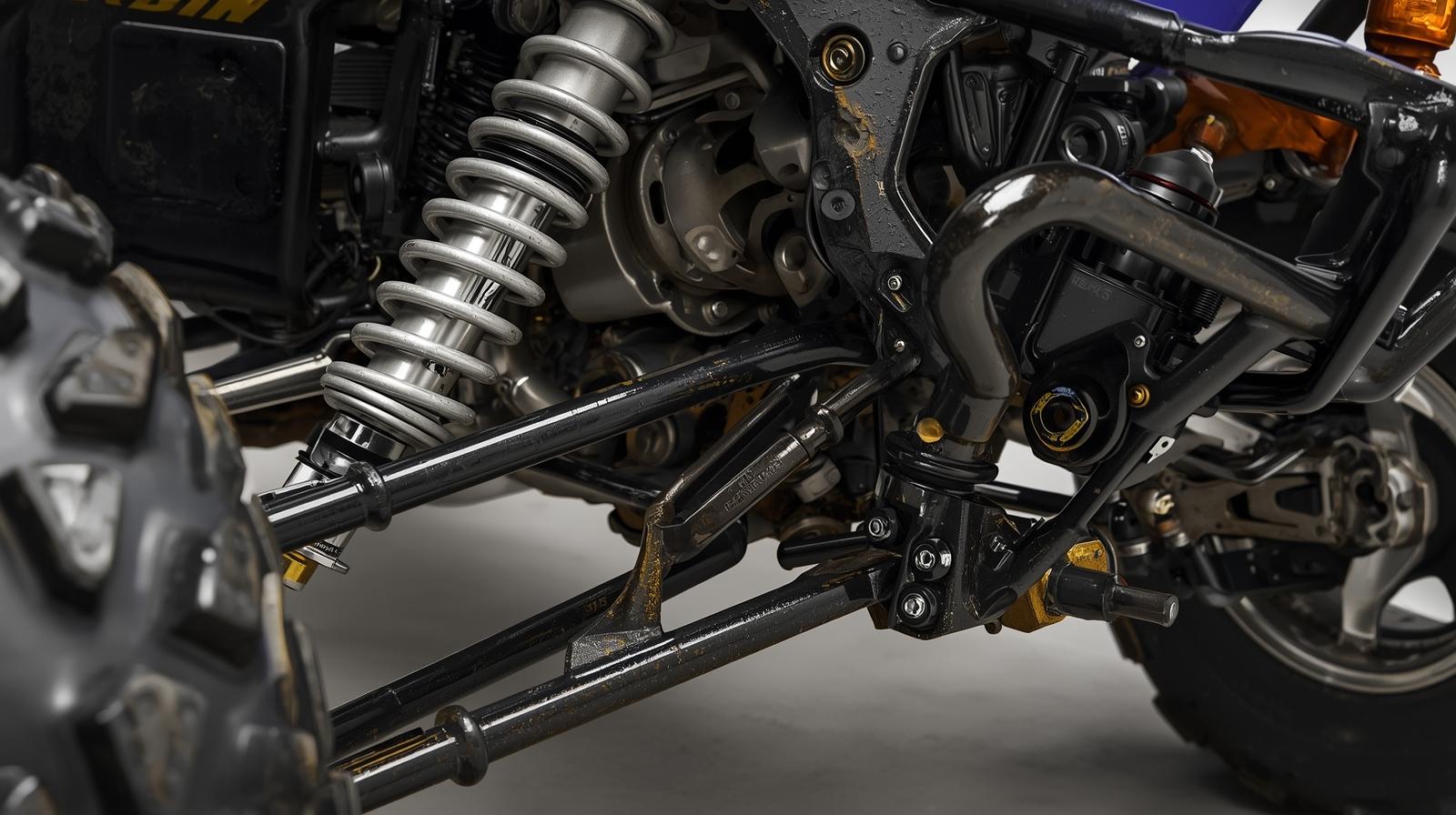

Linkages and Arms: Control wheel alignment and lateral motion.

Modern factories integrate CNC machining, robotic welding, and fatigue-cycle testing to ensure dimensional accuracy and durability across all components.

These processes separate a true suspension parts manufacturer from generic component producers.

Traditional Manufacturing vs. Modern Suspension Engineering

| Aspect | Conventional Production | Modern Suspension Manufacturing |

|---|---|---|

| Material | Standard steel | Heat-treated alloy, aluminum, or composite |

| Damping Control | Manual assembly | Precision-calibrated hydraulic systems |

| Consistency | High variance | Automated testing, CNC tolerance ≤0.02 mm |

| Longevity | 20,000–30,000 km | 50,000+ km under heavy use |

| Quality Verification | Visual inspection | Computerized force and rebound analysis |

Advanced manufacturers now combine hydraulic simulation data with real-world road testing to fine-tune response curves before mass production.

Key Advantages of Modern Suspension Component Manufacturing

1. Enhanced Structural Integrity

Robotic welding and automated tube bending maintain uniform stress distribution, preventing microfractures over time.

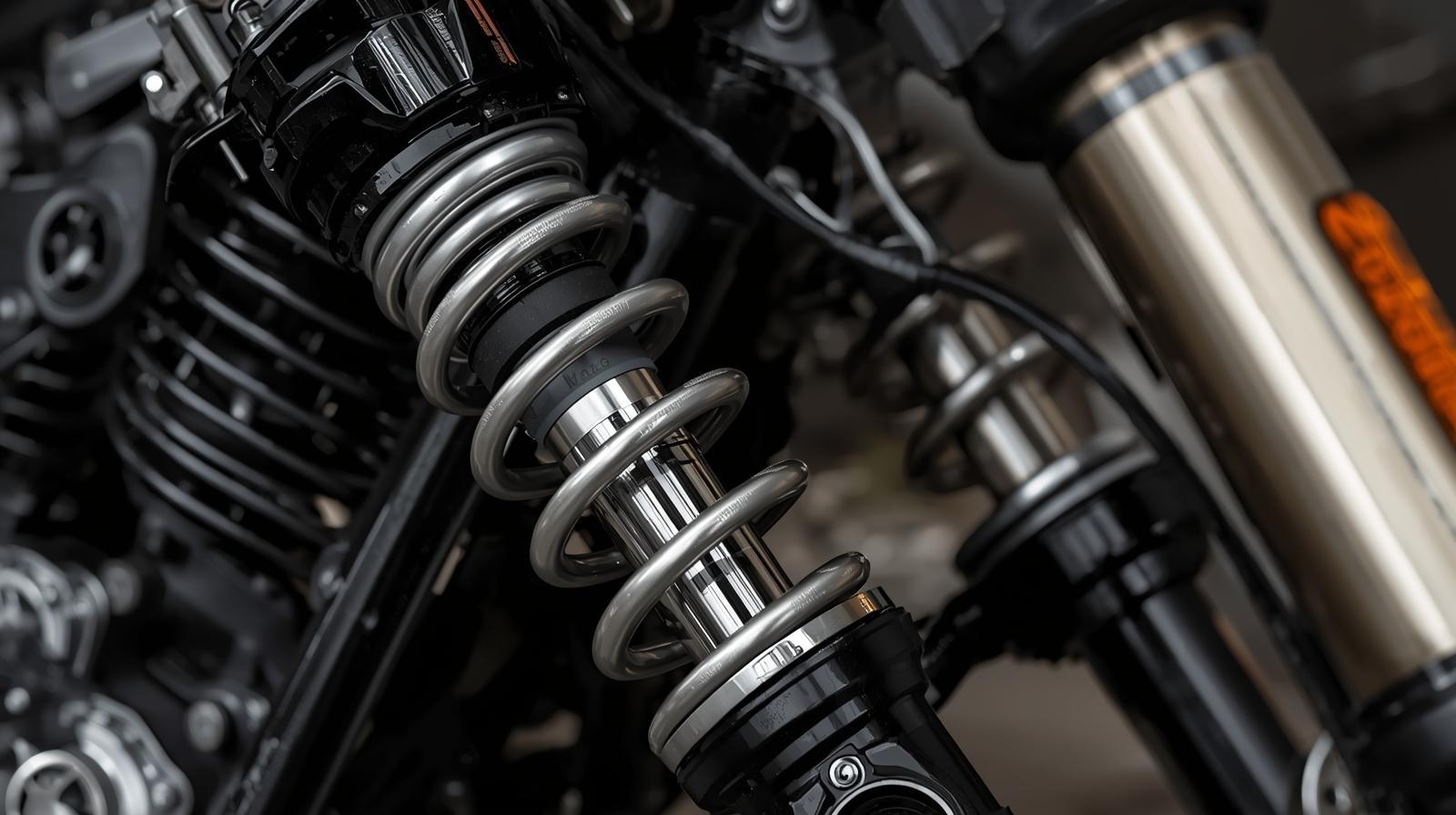

2. Consistent Damping Response

Automated oil-filling systems ensure every shock absorber delivers identical hydraulic pressure across batches.

3. Material Optimization

Alloy compositions are refined for both strength and flexibility, reducing fatigue failure under repeated compression.

4. Global Compatibility

Manufacturers align product geometry and mounting interfaces with international motorcycle and vehicle standards.

5. Lower Lifecycle Cost

Precision-built suspension assemblies minimize maintenance needs, extending replacement intervals for end users.

Applications Across Different Vehicle Categories

-

Motorcycles: Lightweight coil-over assemblies tuned for stability and agility.

-

Automotive Systems: MacPherson and double-wishbone setups for comfort and safety.

-

Off-Road Vehicles: High-travel shocks built to withstand dust, mud, and temperature swings.

-

Electric Models: Low-weight suspensions that compensate for battery placement and torque delivery.

By adapting suspension geometry and damping rates to specific use cases, manufacturers ensure each platform delivers predictable, comfortable performance.

Finding the Right Suspension Partner

When evaluating a supplier, buyers should prioritize these aspects:

| Criterion | What to Look For |

|---|---|

| Certification | ISO 9001 / IATF 16949 compliance for export readiness |

| Customization | Ability to tune coil stiffness and damping to OEM specs |

| Testing Equipment | Endurance rigs, salt spray chambers, and vibration testers |

| MOQ Flexibility | Support for small-batch prototypes and mass production |

| Material Traceability | Complete documentation for steel or alloy sourcing |

A qualified suspension parts manufacturer should be able to provide data-driven assurance, not just product samples.

Common Buyer Questions

Q1: How can performance be validated before mass order?

Through pre-production fatigue and rebound curve testing, with detailed reports shared digitally.

Q2: What’s the average production lead time?

Typically 30–45 days depending on order volume and model complexity.

Q3: Can geometry or branding be customized for OEM clients?

Yes, most factories offer private-label and structural customization services based on CAD drawings.

Q4: Do manufacturers provide technical consultation?

Professional teams assist in matching spring rates, damping ratios, and material choices to project needs.

Driving Reliability Through Manufacturing Excellence

Suspension systems are more than mechanical assemblies—they are the foundation of control and comfort.

The shift from manual assembly to intelligent manufacturing ensures every unit delivers repeatable performance, reducing variability and warranty risk for global distributors.

At Bedo, we focus on producing export-ready suspension systems that combine tested materials, precise damping control, and modular compatibility for different vehicle models.

Our manufacturing process follows ISO and IATF standards, ensuring stability and scalability for both OEM projects and aftermarket brands.

Learn more about our motorcycle and automotive suspension components on our homepage or reach our technical team here.