Rear Suspension Solutions: Reliable Shock Absorbers for Every Ride

Challenges in Modern Motorcycle Suspension

In today’s motorcycle market, achieving a balance between comfort, control, and affordability is a major challenge.

From heavy traffic in urban cities to unpredictable off-road terrain, rear suspension systems must absorb vibration efficiently while maintaining wheel stability.

Traditional units often fall short—oil leaks, inconsistent damping, and rapid wear are common issues that increase maintenance costs and reduce rider confidence.

That’s why both OEM builders and aftermarket distributors now prioritize rear suspension for motorcycles that offer adaptive performance and long-term dependability.

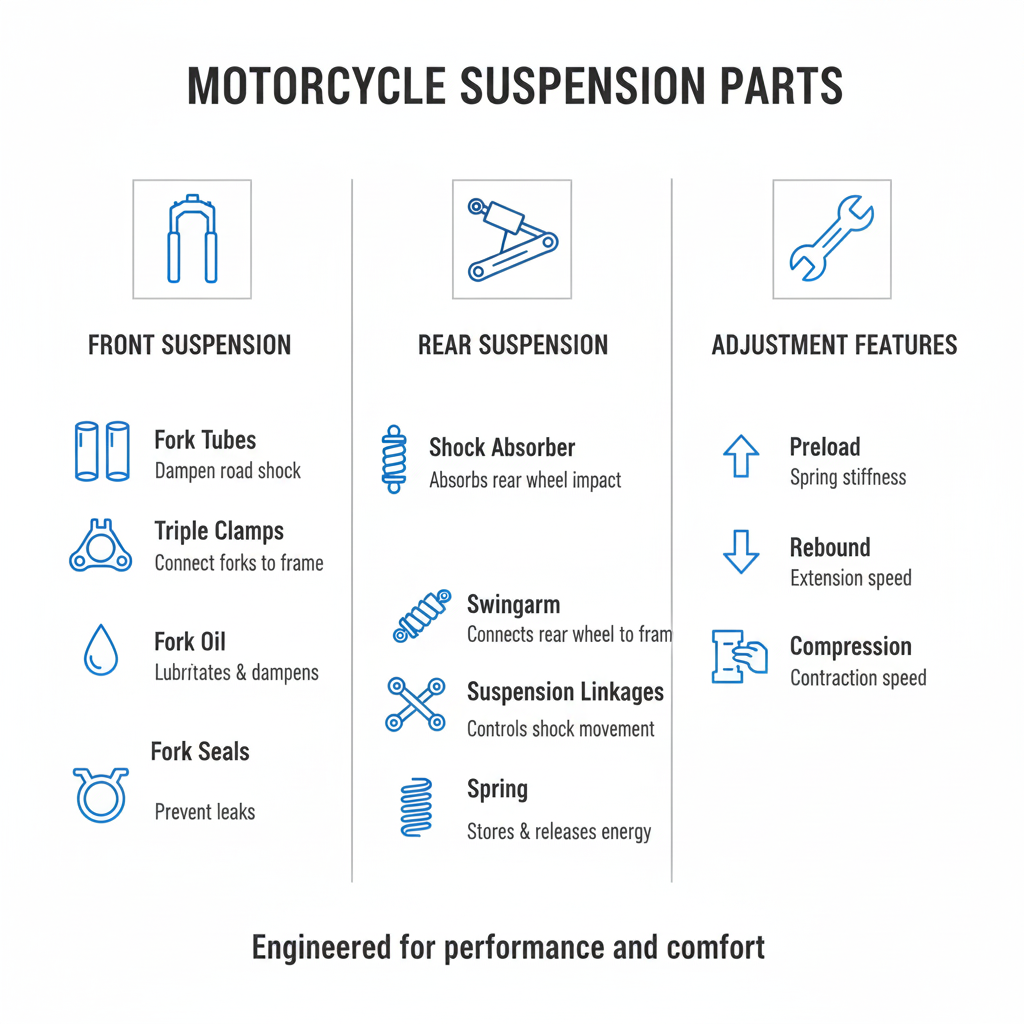

How Rear Suspension Works

A motorcycle’s rear suspension is a dynamic system designed to manage energy transfer between the frame and the road.

By combining spring compression and hydraulic damping, it ensures smooth motion and consistent traction under various riding conditions.

Core Principles:

-

Compression Damping: Prevents bottoming-out on sudden impacts.

-

Rebound Control: Regulates wheel return for stability on uneven terrain.

-

Spring Rate Tuning: Adjusts stiffness based on load and purpose.

-

Hydraulic or Gas Damping: Maintains consistent performance across temperature changes.

The latest manufacturing methods employ gas-charged reservoirs and high-precision seals to deliver smoother damping and extend service life, even under demanding riding cycles.

Conventional vs. Modern Suspension Design

| Feature | Conventional Design | Modern Rear Suspension |

|---|---|---|

| Damping Adjustment | Fixed-rate | Preload and rebound adjustable |

| Material Quality | Carbon steel | Hardened alloy or aluminum |

| Heat Resistance | Fades under stress | Gas-assisted cooling system |

| Service Life | 20,000–30,000 km | 40,000+ km under load |

| Compatibility | Limited by model | Multi-platform OEM adaptable |

| Maintenance | Frequent oil replacement | Sealed or nitrogen-filled units |

This evolution shows how small mechanical upgrades lead to major gains in control, comfort, and overall ride experience.

Advantages of Modern Rear Suspension Systems

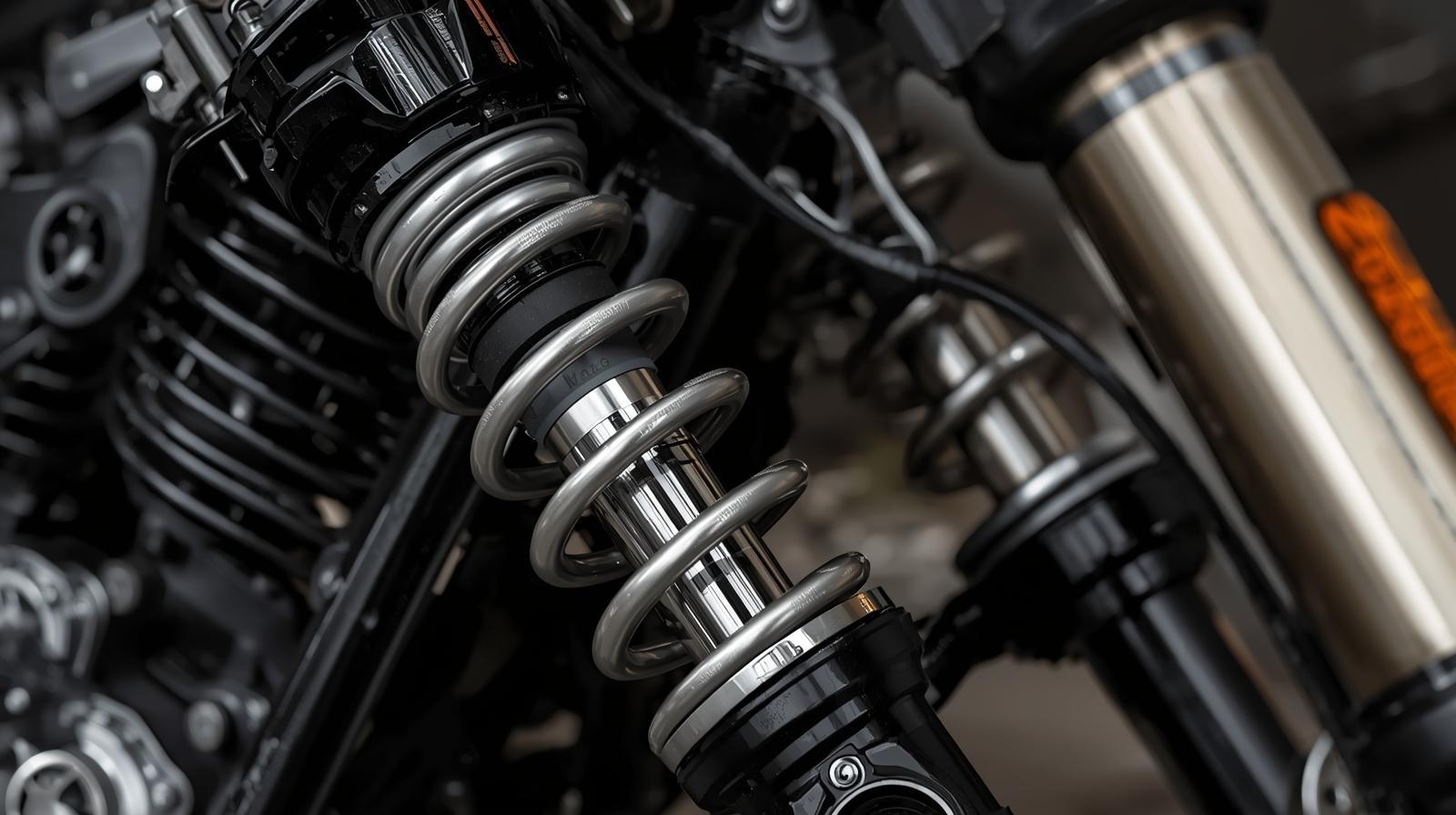

1. Adaptive Ride Comfort

Customizable damping rates allow riders to adjust stiffness for touring, sport, or city use.

2. Cost Efficiency

Improved materials and sealed oil chambers minimize wear and leakage, reducing long-term maintenance costs.

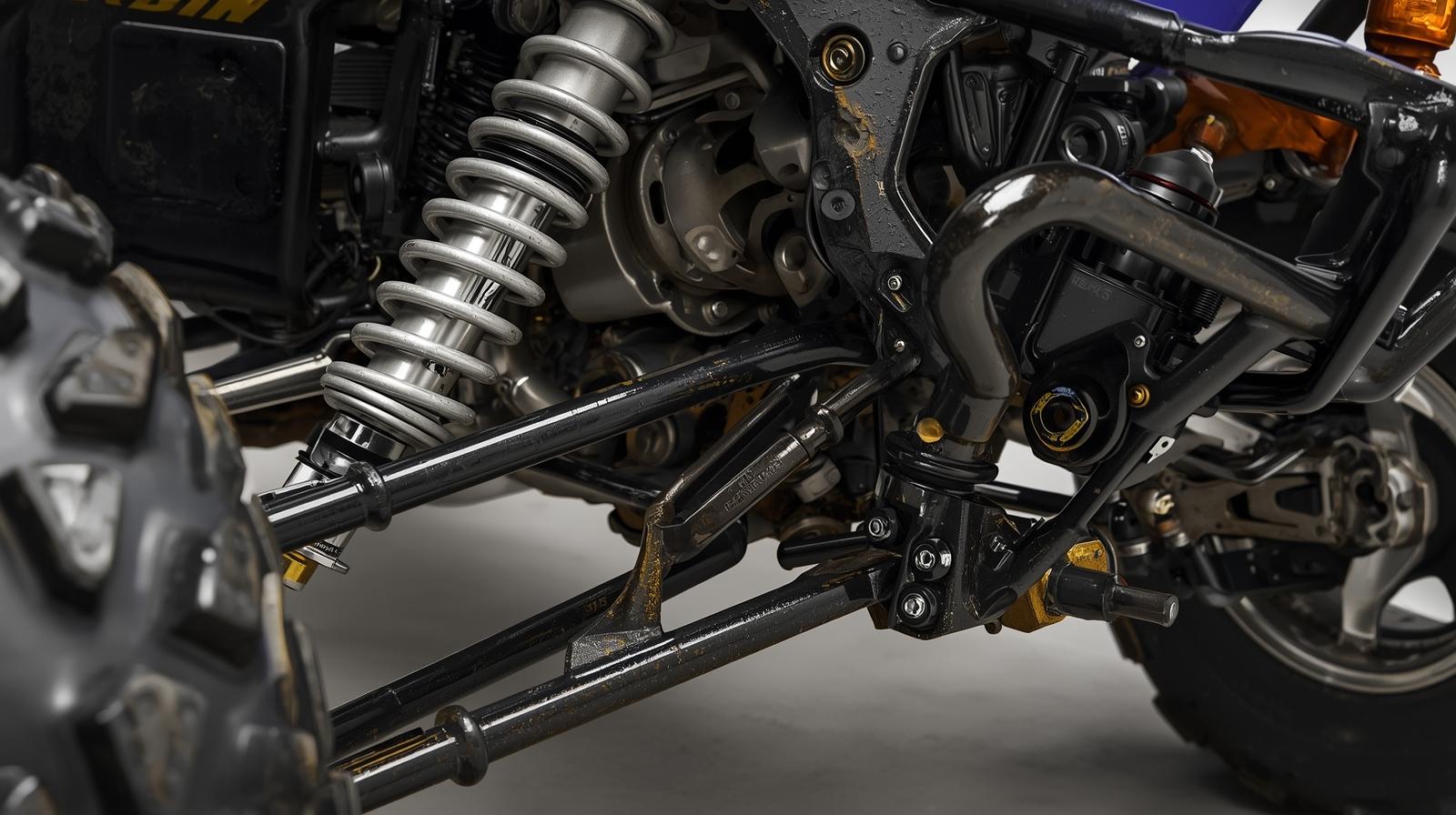

3. Durability Under Load

Dual-spring configurations distribute impact energy evenly, extending service life in heavy-duty or off-road use.

4. Global Compatibility

Modular mounts and standardized fittings make these systems suitable for different motorcycle models and export markets.

5. Consistent Damping Performance

Gas-filled and hydraulic systems maintain smooth operation even under temperature fluctuations or prolonged travel.

Applications Across Motorcycle Segments

-

Urban Commuter Models: Prioritize rider comfort and vibration isolation for daily use.

-

Adventure & Touring Bikes: Require longer travel and higher damping control for unpredictable surfaces.

-

Sport & Racing Models: Focus on precision cornering with adjustable rebound and preload features.

-

Electric Motorcycles: Use lightweight suspension structures optimized for battery balance and torque response.

Across all these categories, rear suspension for motorcycles defines how stable and safe a ride feels, especially under diverse road and climate conditions.

Matching Suspension to Real-World Use

| Usage Scenario | Recommended Setup | Key Benefit |

|---|---|---|

| Daily Commuting | Medium-stiff hydraulic system | Smooth handling & comfort |

| Touring / Long Distance | Gas-charged twin shock | Reduced fatigue, stable damping |

| Off-Road / Adventure | Extended-travel adjustable unit | Strong rebound, better control |

| Performance / Racing | Precision preload system | Responsive handling under speed |

| Heavy-Duty Utility | Dual-spring configuration | High load endurance |

Before finalizing suppliers, it’s important to review vibration test data, coating durability, and ISO compliance to ensure global market readiness.

Common Questions from Buyers

Q1: Can rear suspension be customized for specific motorcycle models?

Yes. Most manufacturers support CAD-based customization to match frame geometry and target damping behavior.

Q2: Are small-batch or pilot production runs available?

Yes. MOQ flexibility supports prototype development and limited-market launches.

Q3: What testing standards should be expected from a quality supplier?

ISO 9001, IATF 16949, and fatigue-cycle testing (≥100,000 compression cycles) are recommended benchmarks.

Q4: What’s the average lifespan in off-road conditions?

Typically, 40,000–50,000 km depending on terrain, load, and maintenance intervals.

Delivering Stability and Confidence, Mile After Mile

Rear suspension systems play a silent yet decisive role in every ride—absorbing shocks, improving traction, and enhancing control.

Modern hydraulic and gas-charged designs make today’s motorcycles more comfortable, reliable, and safer for riders across the world.

At Bedo, our focus is on delivering consistent quality and export-ready suspension solutions tested to international standards.

To learn more about our OEM and aftermarket shock absorber series, visit our homepage or connect with our technical team here.