Custom Motorcycle Coil Springs: Precision Tuning for Every Ride Condition

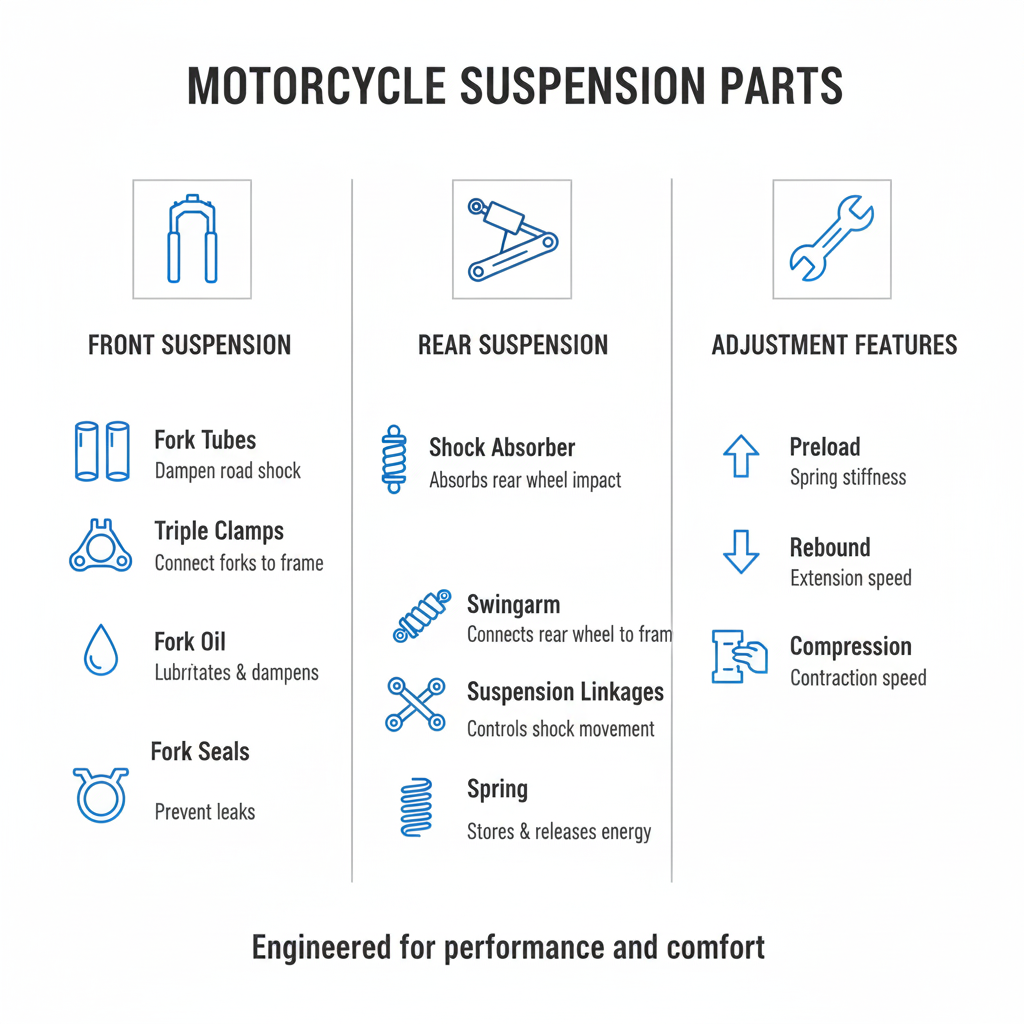

Understanding the Role of Coil Springs in Modern Motorcycles

The coil spring is more than just a component—it’s the backbone of every motorcycle’s suspension system. It defines how the vehicle responds to bumps, corners, and weight transfer. While standard springs are designed for average use, custom motorcycle coil springs are tailored to individual riding styles, terrains, and load capacities, offering optimized control without sacrificing comfort.

Whether it’s a touring bike handling long-distance travel or an off-road model built for unpredictable terrain, customization ensures that each setup delivers the right balance of stiffness, rebound, and damping harmony.

How Customization Shapes Performance

Custom coil spring design begins with three core parameters: wire diameter, pitch, and material elasticity.

Each of these directly influences how a spring compresses and rebounds under different loads.

Key Engineering Factors:

-

Material Strength: High-carbon or chrome-silicon alloys maintain consistent elasticity and fatigue resistance.

-

Heat Treatment: Controlled tempering prevents deformation after prolonged use.

-

Shot Peening: Adds surface compression to extend lifespan under cyclic load.

-

Progressive Winding: Adjusts stiffness throughout compression, ideal for mixed-terrain motorcycles.

By adjusting these factors, manufacturers create coil springs that perform equally well under highway speeds or aggressive cornering.

Conventional vs. Custom Coil Spring Design

| Parameter | Standard Coil Spring | Custom Motorcycle Coil Spring |

|---|---|---|

| Spring Rate | Fixed | Adjustable to rider weight & bike type |

| Wire Type | Uniform | Variable diameter for progressive response |

| Material | Carbon steel | Chrome-silicon alloy or titanium |

| Surface Coating | Basic paint | Powder coating or anti-corrosion finish |

| Durability | 20,000 km average | Up to 50,000 km with consistent rebound |

Customized coil springs outperform mass-produced ones by aligning technical specs with real-world demands—resulting in smoother rides, reduced bottoming-out, and greater frame longevity.

Advantages for OEMs and Global Buyers

-

Enhanced Load Adaptability

Custom coil springs distribute forces more evenly, improving balance during acceleration, braking, and turning. -

Longevity in Harsh Conditions

Special surface finishes resist corrosion from road debris, moisture, and salt—critical for export markets. -

Reduced Maintenance Downtime

Better fatigue resistance extends replacement intervals and minimizes shock absorber stress. -

Tailored Manufacturing Options

Low MOQ and modular tooling enable easy model adaptation without reengineering costs. -

Global Supply Compatibility

Standardized dimensions ensure seamless integration with existing suspension assemblies.

Applications and Customization Scenarios

-

Sport Motorcycles: Progressive coil designs for sharp cornering and consistent rebound.

-

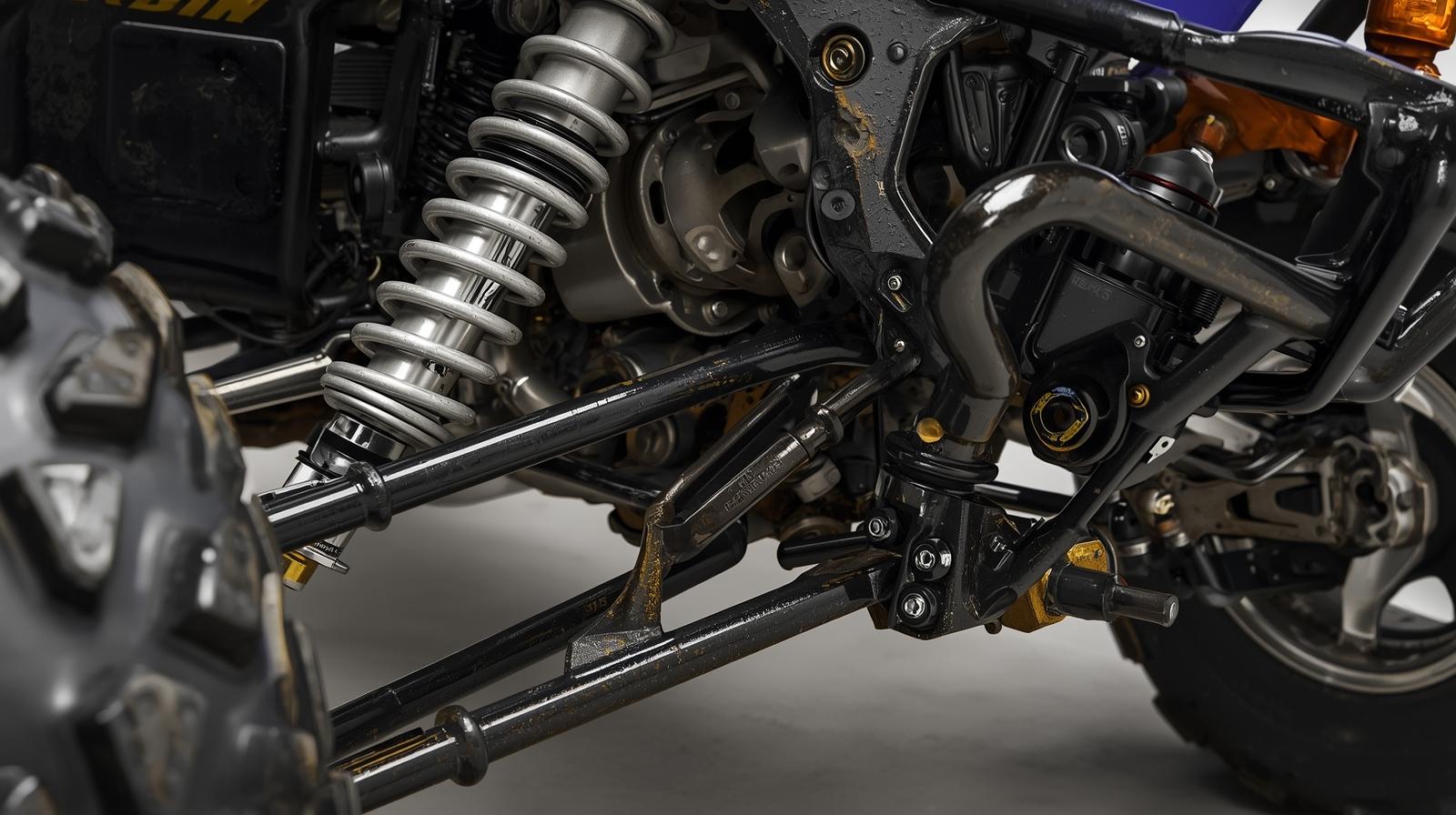

Off-Road & Adventure Bikes: Heavy-duty coils tuned for impact absorption and stability on uneven ground.

-

Touring Motorcycles: Softer rates for comfort during long-distance travel.

-

Electric Motorcycles: Lightweight titanium coils optimized for energy efficiency and torque response.

These applications demonstrate why custom motorcycle coil springs are now essential for brands pursuing differentiation in ride feel and performance consistency.

Practical Selection Tips for Buyers

| Riding Condition | Recommended Coil Type | Spring Rate |

|---|---|---|

| City / Commuting | Medium-stiff linear spring | 9–11 N/mm |

| Touring / Long Distance | Softer dual-rate spring | 6–8 N/mm |

| Racing / Track Use | Progressive wound spring | 12–14 N/mm |

| Heavy-Duty / Cargo | Reinforced steel coil | 15–18 N/mm |

When sourcing, prioritize manufacturers offering fatigue testing data, coating thickness certification, and dynamic load curve charts for full transparency.

Buyer FAQs

Q1: Can small batch customization be supported?

Yes. Low MOQ production is available for pilot runs or new model trials.

Q2: What material options are most suitable for export markets?

Chrome-silicon and stainless alloys provide optimal strength-to-weight ratio and corrosion resistance.

Q3: Can the coil color or finish be customized for brand models?

Absolutely. Powder coating, anodizing, and custom color-matching are all available for OEM differentiation.

Q4: What lifespan can be expected from custom motorcycle coil springs?

Typically 50,000 km+ with proper damping matching and maintenance intervals.

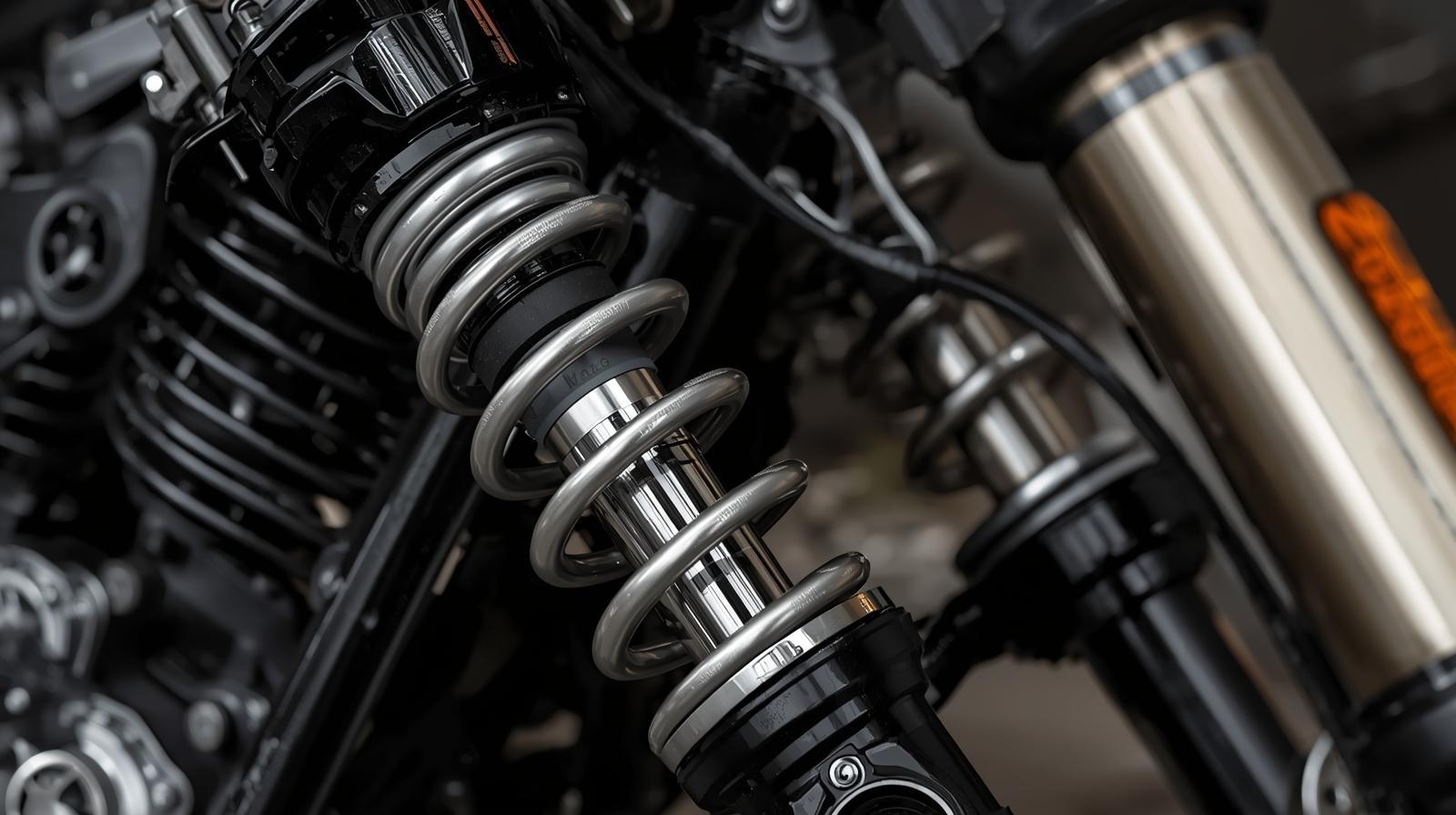

Delivering Long-Term Ride Stability

Custom-built coil springs form the foundation of motorcycle stability. They respond dynamically to terrain, absorb vibration, and maintain balance across thousands of load cycles.

Through advanced material science and precision winding technology, manufacturers now provide suspension components that elevate both rider comfort and brand reliability.

To learn more about tailored coil spring solutions and technical customization options, visit our homepage or connect with our engineering team here.