Custom Coil Spring Manufacturer for UTV: Precision-Built Suspension for Extreme Terrain

The Challenge of UTV Suspension Design

A UTV isn’t just a recreational machine — it’s a workhorse designed for hauling, towing, and surviving the toughest trails.

Yet, behind every smooth ride over mud, rock, or sand lies an intricate balance between spring tension, damping precision, and frame geometry.

Most factory-fitted springs are general-purpose; they serve “just fine” for mixed conditions.

But off-road racers, agricultural operators, and industrial users know better.

When carrying heavy loads or maneuvering sharp turns at speed, these stock springs struggle — uneven compression, premature fatigue, and heat buildup become real problems.

That’s where custom coil spring manufacturing enters the picture — not as luxury, but necessity.

Engineering Logic Behind Custom Coil Springs

Every coil spring is defined by three invisible parameters:

material strength, load response, and recovery speed.

Changing any of them reshapes how a UTV feels on the trail.

-

Material Selection: Chrome-silicon alloys, for instance, resist deformation far better than carbon steel under cyclic compression.

-

Heat Treatment: Controlled tempering allows micro-structural consistency — each coil retains its elasticity through thousands of flex cycles.

-

Progressive Winding: By varying the pitch of the coil, manufacturers create springs that adjust stiffness gradually as they compress, perfect for mixed terrain.

The result? Suspension that reacts to the ground instead of fighting it.

Such tuning defines what a true custom coil spring manufacturer for UTV offers: responsive handling when empty, steady control when loaded.

Traditional vs. Custom UTV Spring Systems

| Feature | Standard Springs | Custom Coil Springs (OEM Level) |

|---|---|---|

| Load Response | Fixed rate | Variable or progressive rate |

| Material | Basic carbon steel | Chrome-silicon or titanium |

| Fatigue Life | 20,000 cycles | 50,000+ under full load |

| Adaptability | Single terrain | Tuned per model and usage |

| Finish | Painted | Powder-coated / shot-peened anti-corrosion |

| Application | Recreational use | Heavy-duty & commercial utility |

A properly tuned spring system transforms UTV behavior — reducing sway in tight corners, absorbing shocks from rock gardens, and keeping all four tires grounded during high-speed runs.

Advantages of Custom Manufacturing for UTV Suspension

1. Tailored Damping Behavior

Each UTV model carries different weight distribution — rear-load bias, front-heavy utility setups, or even side-by-side passenger imbalance. Custom coil springs compensate precisely for these load patterns.

2. Extended Component Life

Better surface finishing and precise metallurgical treatment drastically slow down fatigue failure and corrosion, reducing the frequency of suspension rebuilds.

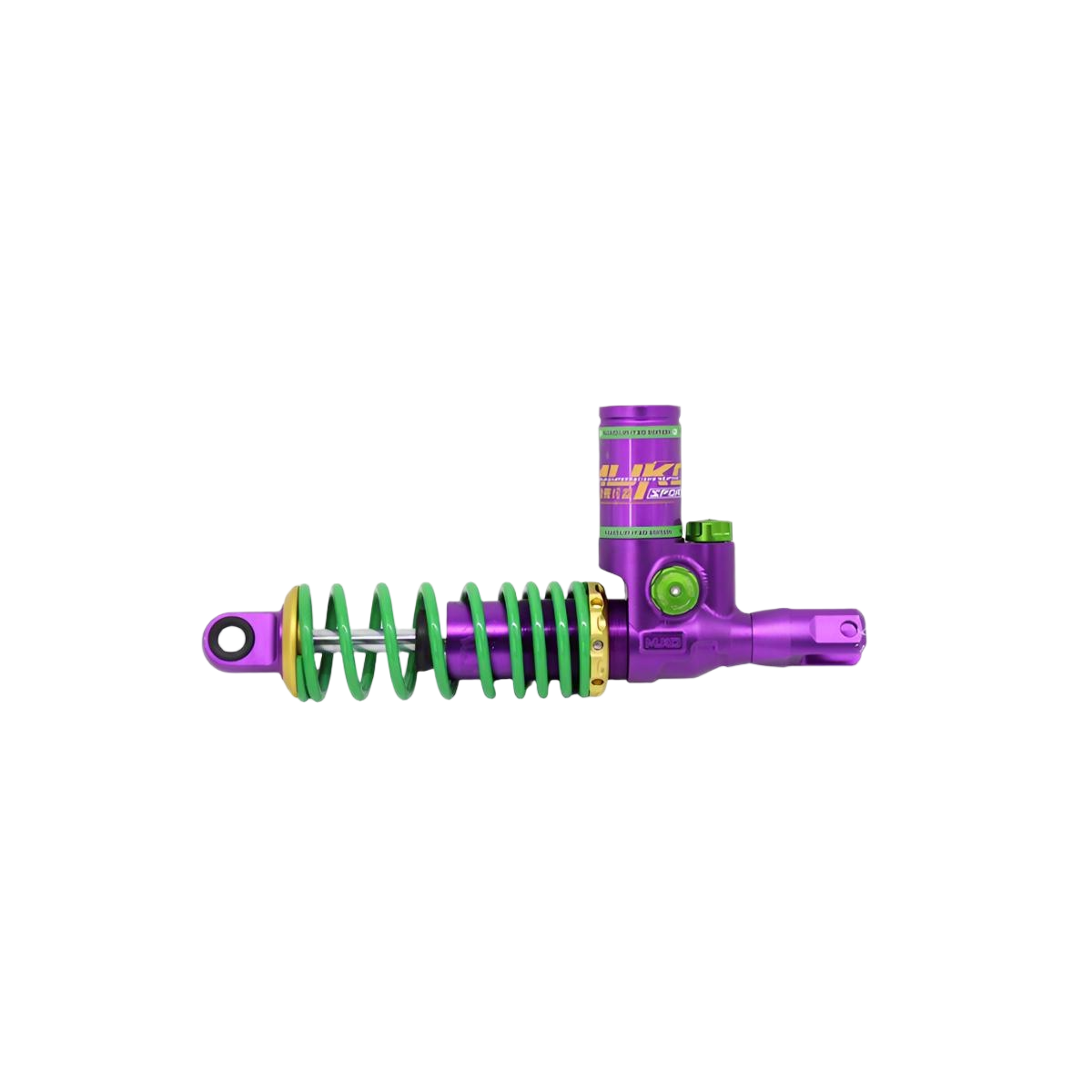

3. Compatibility with Performance Shocks

High-end gas-charged dampers require perfectly matched spring constants. Custom suppliers ensure harmonized spring rates for advanced UTV shock absorber systems.

4. Scalable OEM Integration

Modern suppliers provide CAD data, prototype validation, and ISO-compliant traceability — critical for OEM brands exporting to North America and Europe.

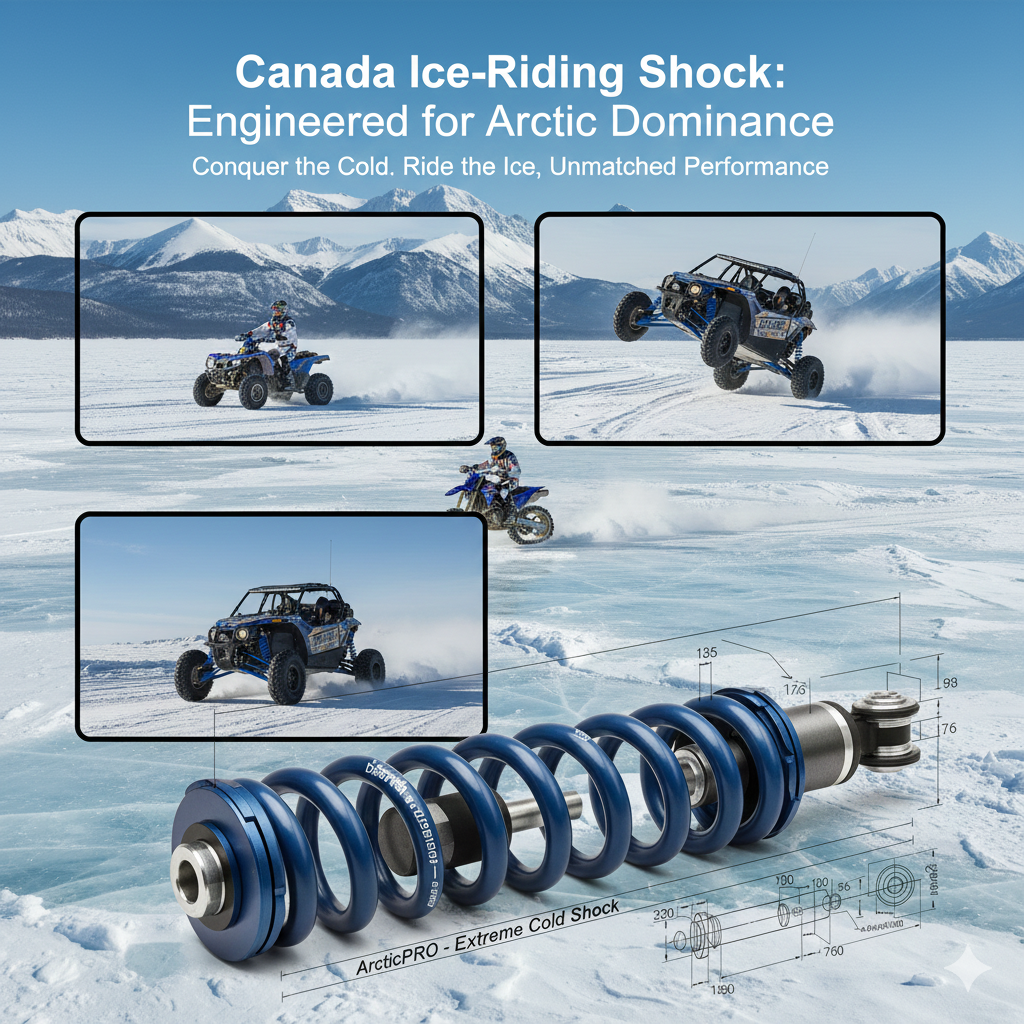

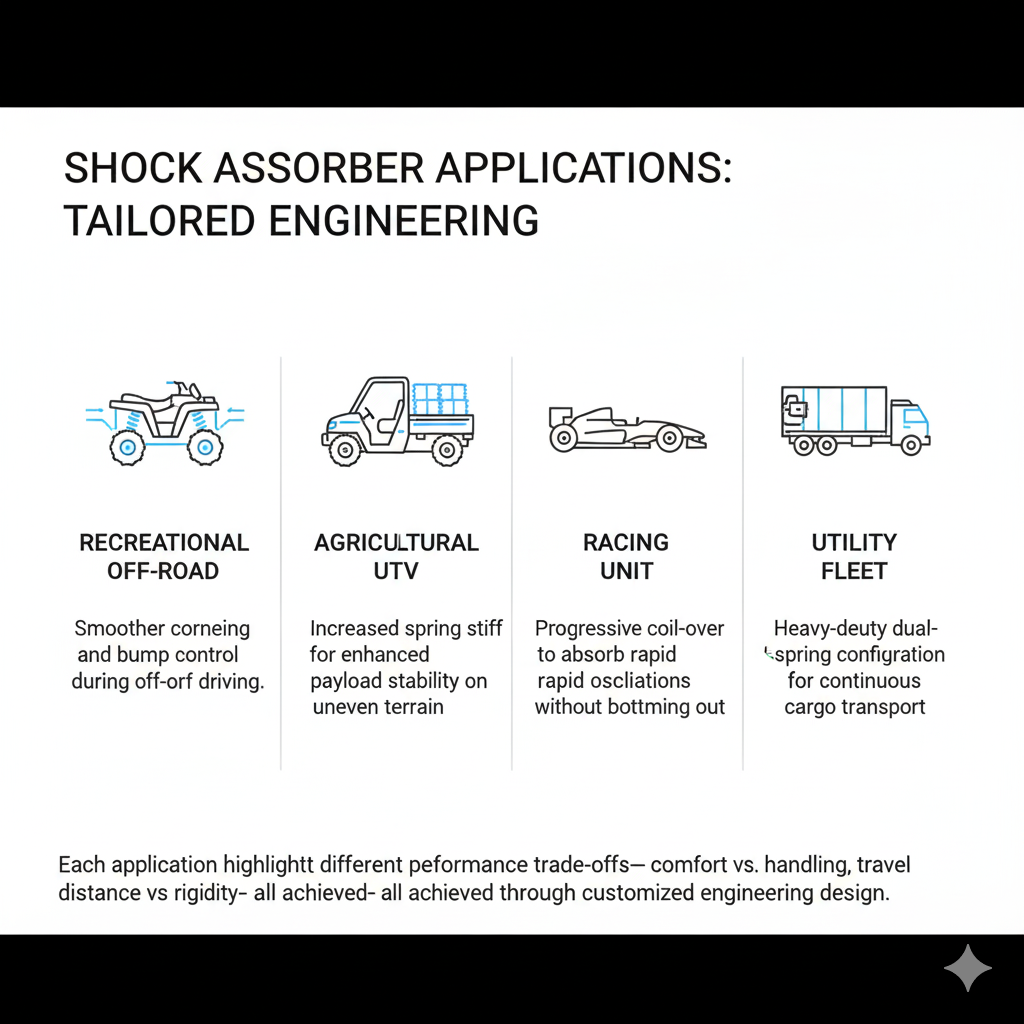

Real-World Applications

-

Recreational Off-Road Vehicles: Smoother corner entry and bounce control during trail rides.

-

Agricultural UTVs: Increased spring stiffness for payload stability on uneven terrain.

-

Racing Units: Progressive rate coils that absorb rapid oscillations without bottoming out.

-

Utility Fleets: Heavy-duty dual-spring configurations for constant cargo transport.

Each application emphasizes a different performance trade-off — comfort versus control, travel distance versus rigidity — all achieved through meticulous custom engineering.

Selection Guide: What Buyers Should Consider

| Criterion | Recommendation | Reason |

|---|---|---|

| Load Rating | Define based on payload + terrain type | Prevents under-springing or over-stiffness |

| Material | Chrome-silicon or titanium alloys | Superior fatigue and corrosion resistance |

| Surface Treatment | Shot-peening + powder coating | Extends service life |

| Damping Compatibility | Match with adjustable shock absorber | Maximizes stability |

| MOQ Flexibility | Look for 100–200 set production support | Ideal for prototype and OEM testing |

Selecting a qualified UTV coil spring manufacturer means verifying both engineering expertise and supply chain agility.

Common Buyer Questions

Q1: Can custom springs be designed for lifted or modified UTVs?

Yes. Engineers can adjust free length and coil count to maintain correct preload after lift-kit installation.

Q2: How long does fatigue testing take for OEM certification?

Most durability tests run between 80,000–100,000 compression cycles under load simulation.

Q3: Are dual-rate or progressive springs better for utility UTVs?

Progressive coils offer more comfort across variable terrains, while dual-rate springs perform best under constant heavy load.

Q4: What export standards are required for global shipment?

ISO 9001, IATF 16949, and RoHS compliance are generally mandatory for international buyers.

Precision That Powers Performance

Custom coil springs are not just parts — they are the unsung architecture of motion.

Every bend, every rebound, every smooth landing tells the story of engineering decisions made in the factory long before the trail began.

A true custom coil spring manufacturer for UTV brings together metallurgy, mathematics, and motion — creating suspension components that adapt, endure, and elevate performance.

To explore tailored spring solutions for your next UTV platform, visit our homepage or connect with our technical team here.