Understanding Buggy Shock Absorber Rebuild Parts

When it comes to maintaining the performance and safety of your off-road buggy, investing in high-quality buggy shock absorber rebuild parts is essential. These components are the backbone of your vehicle's suspension system, ensuring smooth rides over rugged terrain while absorbing shocks and vibrations. As an enthusiast or professional racer, selecting the right rebuild parts can significantly extend the life of your shocks, preventing costly replacements and enhancing overall handling. In this article, we'll dive into the intricacies of buggy shock absorber rebuild parts, exploring their role, selection, and maintenance to help you make informed decisions for your next upgrade.

The Importance of Rebuilding Your Buggy Shocks

Buggy shock absorber rebuild parts allow you to restore your existing shocks to like-new condition rather than discarding them entirely. Over time, shocks endure immense stress from jumps, bumps, and high-speed maneuvers, leading to wear on seals, bushings, and internal valves. By using rebuild kits that include pistons, oil, and O-rings, you can rejuvenate these critical components. This process not only saves money but also maintains the original tuning specifications of your shocks, which is vital for buggies designed for specific racing classes or recreational use. For instance, off-road buggies often require shocks that can handle extreme angles and impacts, and proper rebuilding ensures they continue to provide that necessary damping control.

The benefits extend beyond cost savings. Rebuilt shocks with fresh buggy shock absorber rebuild parts contribute to better vehicle stability, reducing the risk of rollovers or loss of control during aggressive driving. Moreover, in competitive environments like dune buggies or desert racing, reliable suspension is a game-changer. Regular maintenance using these parts can prevent fluid leaks and corrosion, keeping your buggy responsive and safe. Enthusiasts often report improved ride quality after a rebuild, with smoother transitions over obstacles and less fatigue during long sessions.

Key Components in Buggy Shock Absorber Rebuild Kits

A typical set of buggy shock absorber rebuild parts includes a variety of specialized elements tailored for the demands of off-road vehicles. Starting with the seals and wipers, these prevent dirt and debris from entering the shock body, a common issue in dusty or muddy environments. High-quality polyurethane or rubber seals ensure a tight fit, maintaining hydraulic pressure for optimal performance. Next, the piston and rod assemblies are crucial; they control the flow of shock oil, dictating how quickly the shock compresses and rebounds. For buggies, choosing parts with adjustable valving options allows customization for softer landings or firmer control, depending on your setup.

Don't overlook the bushings and bearings, which reduce friction and allow smooth movement. In rebuild kits, these are often upgraded to spherical bearings for enhanced articulation, ideal for buggies with long-travel suspensions. Shock oil is another vital part—selecting the right viscosity, such as lightweight for high-speed desert runs or heavier for rock crawling, can fine-tune your ride. Finally, the external components like reservoirs and bump stops should be inspected and replaced if necessary during the rebuild. These elements work together to ensure your shocks can withstand the torque and heat generated in buggy applications, providing consistent performance lap after lap.

Selecting the Best Buggy Shock Absorber Rebuild Parts for Your Vehicle

Choosing the right buggy shock absorber rebuild parts starts with understanding your buggy's specifications. Measure the shock length, diameter, and travel to match compatible kits from reputable brands like Fox, King, or Bilstein, which offer durable parts designed for extreme conditions. Consider the type of terrain you frequent—sand dunes demand parts with excellent heat dissipation, while rocky trails require robust seals to handle abrasions. It's also wise to opt for kits that include all necessary hardware, such as circlips and spacers, to avoid incomplete rebuilds.

Compatibility is key; ensure the parts align with your shock's valving and mounting style, whether it's eyelet or clevis ends common in buggies. Reading user reviews and consulting with suspension experts can guide you toward parts that have proven track records in similar vehicles. For those upgrading to a state-of-the-art automotive suspension coilover, integrating rebuild parts that complement advanced features like adjustability can elevate your buggy's performance. Look for kits with cutting-edge materials, such as polished stainless steel components for corrosion resistance, ensuring longevity even in harsh environments. This approach not only restores but enhances your suspension, blending functionality with a sleek aesthetic through elements like vibrant accents that appeal to modification enthusiasts.

Step-by-Step Guide to Rebuilding Your Buggy Shocks

Rebuilding buggy shocks with dedicated rebuild parts is a rewarding DIY project that requires precision and the right tools. Begin by safely removing the shocks from your vehicle, using a jack and stands for stability. Disassemble the shock body carefully, noting the orientation of washers and shims to replicate during reassembly. Clean all components thoroughly with a solvent to remove old oil and grime, inspecting for any irreparable damage like bent rods.

Once clean, replace worn parts starting with the seals—use a seal driver tool to install them without twisting. Install the new piston and fill the shock with the appropriate oil, bleeding air bubbles by cycling the shaft multiple times. For buggies, pay special attention to the rebound and compression valving stacks, adjusting them based on your riding style. Reassemble the body, torque everything to manufacturer specs, and test for leaks. This process, when done with quality buggy shock absorber rebuild parts, can restore your shocks to perform as well as—or better than—new, providing superior handling and stability.

After rebuilding, bench-test the shocks if possible, or take a short test drive on familiar terrain to verify performance. Professional installation is an option for complex setups, but many buggy owners find the hands-on rebuild satisfying and educational. Regular rebuilds every 50-100 hours of use keep your suspension in top shape, preventing downtime during events or adventures.

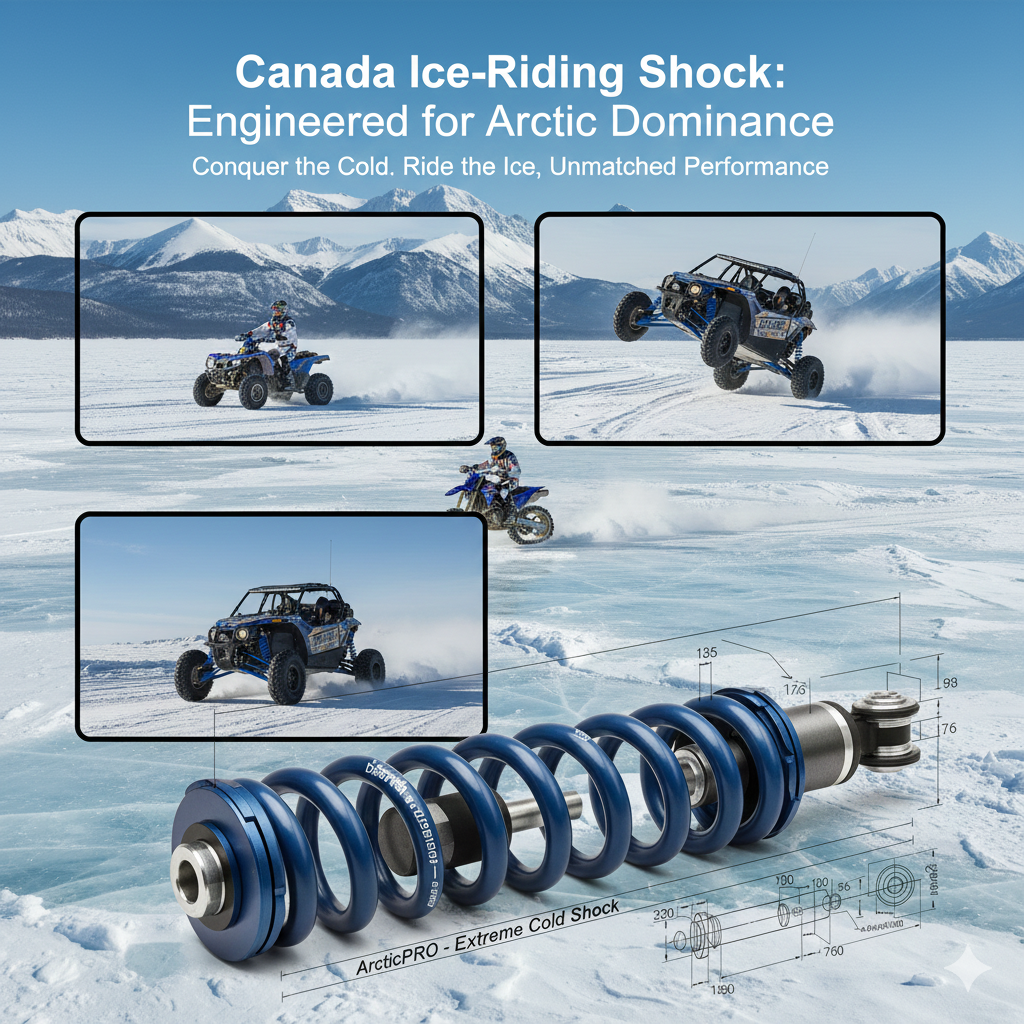

Enhancing Performance with Upgraded Suspension Solutions

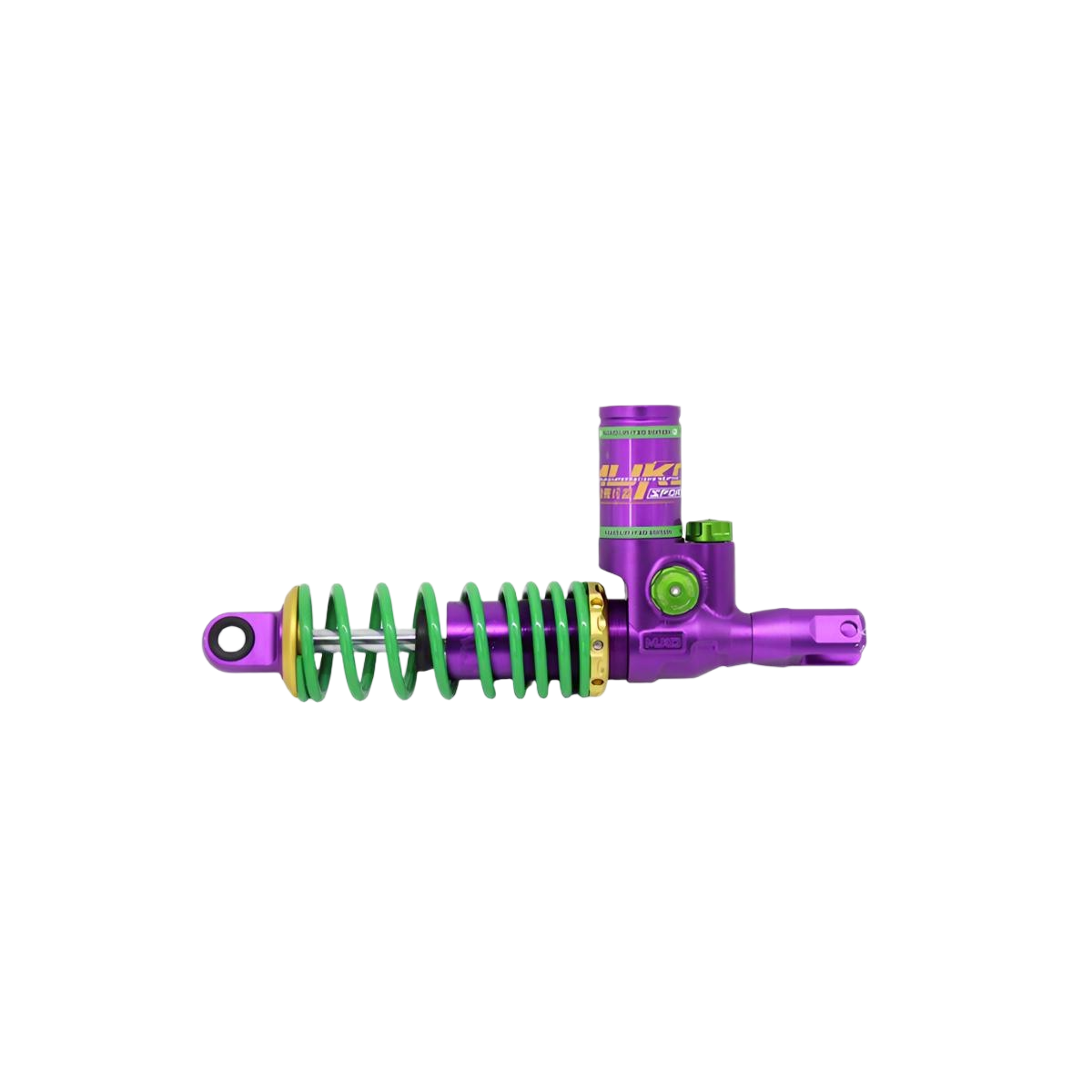

While buggy shock absorber rebuild parts are indispensable for maintenance, pairing them with modern upgrades like a premium coilover can transform your buggy's capabilities. Imagine a suspension coilover engineered with precision, featuring a polished stainless steel body for unmatched durability and a stylish appearance that turns heads at meets. The vibrant orange accents not only add a bold visual pop but also highlight the high-end engineering, including effortless adjustability for ride height and damping to adapt to any condition—from smooth trails to intense jumps.

These coilovers are crafted with expertly designed coils that deliver superior stability, making them ideal for both casual drivers and racers seeking that perfect blend of comfort and control. The robust construction promises longevity, making it a smart investment for automotive excellence. When rebuilding your existing shocks, consider how these advanced components can integrate, offering a comprehensive upgrade that elevates your buggy's off-road prowess. By focusing on quality parts and innovative designs, you ensure your vehicle remains reliable and exhilarating for years to come.

Maintenance Tips and Long-Term Care

To maximize the lifespan of your rebuilt shocks using buggy shock absorber rebuild parts, adopt a proactive maintenance routine. After every outing, inspect for leaks, loose fittings, or unusual noises. Clean the externals regularly to prevent buildup of mud and salt, which can accelerate wear. Store your buggy in a dry environment to avoid corrosion, and schedule full rebuilds based on usage—more frequent for competitive driving.

Additionally, monitor tire pressure and alignment, as these affect shock stress. Using the right lubricants during rebuilds and avoiding over-extension of travel will further enhance durability. For those incorporating coilover systems, periodic adjustments ensure optimal performance. With these practices, your buggy's suspension will consistently provide the comfort and control needed for thrilling adventures, proving that well-maintained parts are the key to sustained excellence in off-road motoring.

In summary, buggy shock absorber rebuild parts are more than just replacements; they're a pathway to revitalizing your vehicle's core dynamics. By selecting, installing, and maintaining them thoughtfully, alongside potential upgrades like advanced coilovers, you'll enjoy enhanced safety, performance, and style on every ride.