Audited Motorcycle Suspension Parts Maker: Verified Quality for Global Buyers

Why Factory Audits Matter More Than Ever

In an industry where dozens of factories promise “OEM quality,” documentation tells only half the truth.

The difference between claims and capability is discovered during an audit.

An audited motorcycle suspension parts maker has proven control over material sourcing, process stability, and traceability.

For buyers balancing cost, performance, and brand reputation, that verification is not optional — it’s insurance.

A missing certificate can delay customs clearance.

An undocumented change in steel supplier can alter spring rates.

These details decide whether a brand thrives or loses trust overnight.

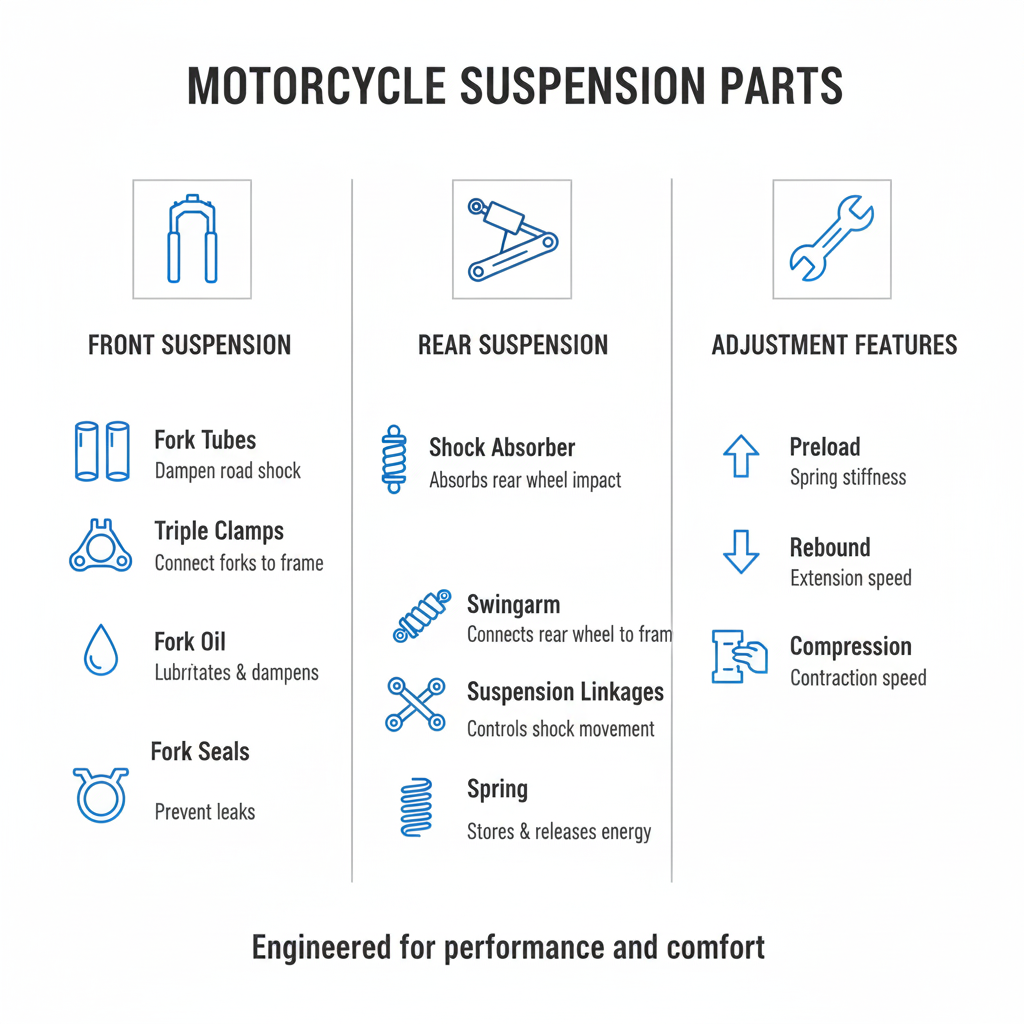

Inside an Audit: What Is Actually Verified

Audits go far beyond checking paperwork. They dissect how every component is built.

1. Material Traceability – Inspectors match heat-batch numbers of alloy rods, tubing, and oil seals against purchase records.

2. Process Capability (Cp/Cpk) – Statistical charts confirm machining repeatability within ± 0.02 mm.

3. Quality Gates – Each assembly line must include torque and oil-fill verification checkpoints.

4. Testing Equipment Calibration – Damping curve benches, salt-spray chambers, and fatigue rigs are cross-checked with calibration logs.

5. Workforce Training & EHS Compliance – Worker certification, safety signage, and chemical handling routines are evaluated.

A pass means the factory can consistently deliver export-grade suspension parts — not just prototypes that look good in photos.

Audited vs. Non-Audited Manufacturers

| Category | Audited Maker | Non-Audited Factory |

|---|---|---|

| Process Control | ISO 9001 / IATF 16949 certified | Undefined or local QC only |

| Documentation | Full traceability & inspection reports | Manual records, no batch linkage |

| Product Testing | Certified damping, fatigue, & salt-spray tests | Spot checks only |

| Consistency | ± 5 % tolerance across batches | ± 15 % or more |

| Buyer Assurance | Third-party validation | Reliance on self-reporting |

The audit doesn’t make production slower; it makes it predictable — every shipment built to the same mechanical rhythm.

Core Advantages of Audited Suspension Production

1. Verified Raw Materials

Suppliers must disclose mill certificates and chemical composition reports, ensuring every spring wire meets tensile-strength standards.

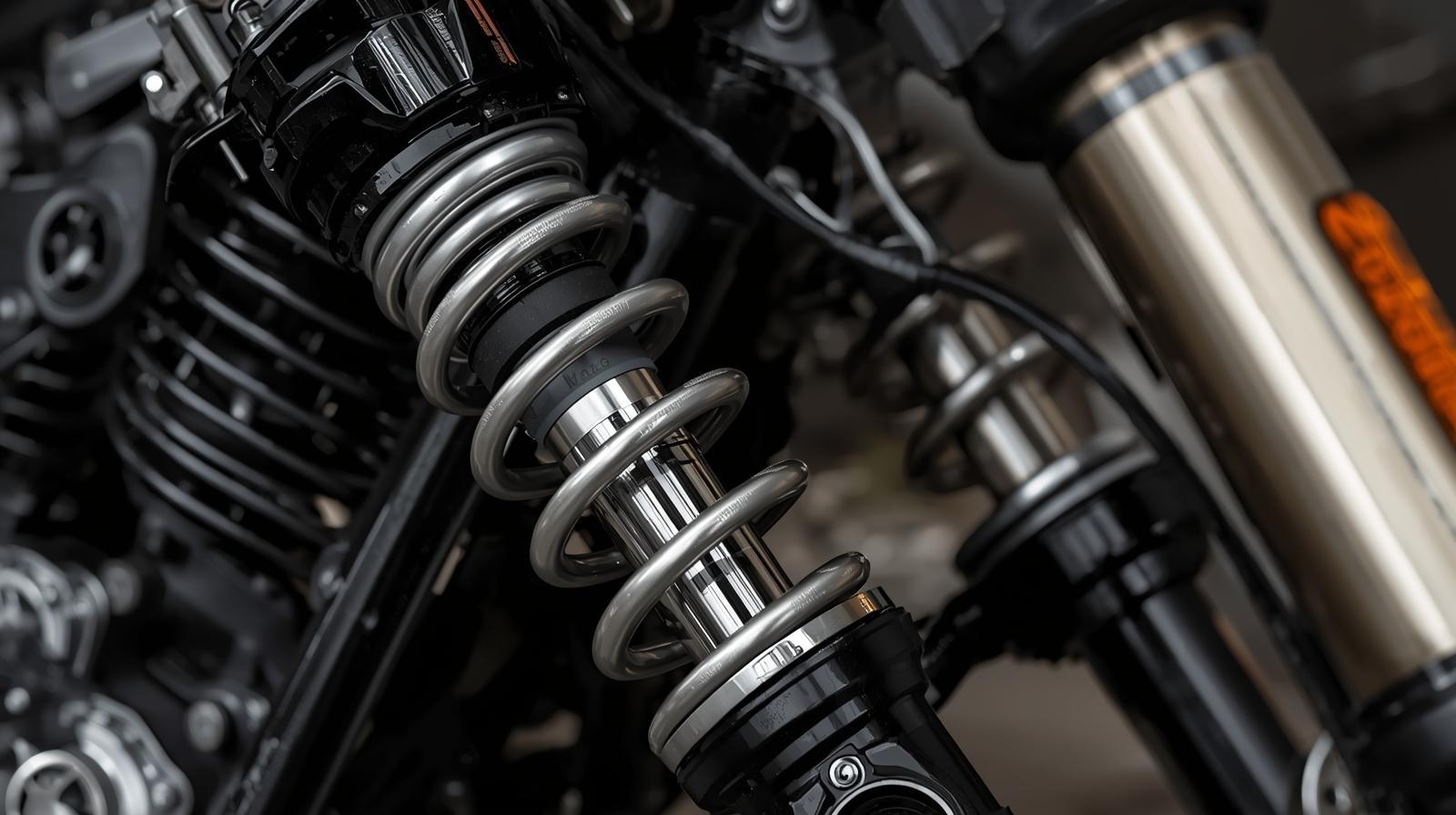

2. Stable Damping Characteristics

Audited lines measure rebound and compression curves against reference data before packaging.

3. Lower Claim Ratio

Traceable serial numbers simplify post-sale analysis, reducing warranty disputes.

4. OEM Readiness

Compliant documentation (PPAP, IMDS) accelerates project approval for international brands.

5. Ethical & Environmental Compliance

Audited plants demonstrate RoHS, REACH, and labor-practice conformity — now a must for EU and US importers.

Applications Across the Motorcycle Industry

-

Commuter & Urban Bikes: Reliable shocks with tight QC for high-volume OEM builds.

-

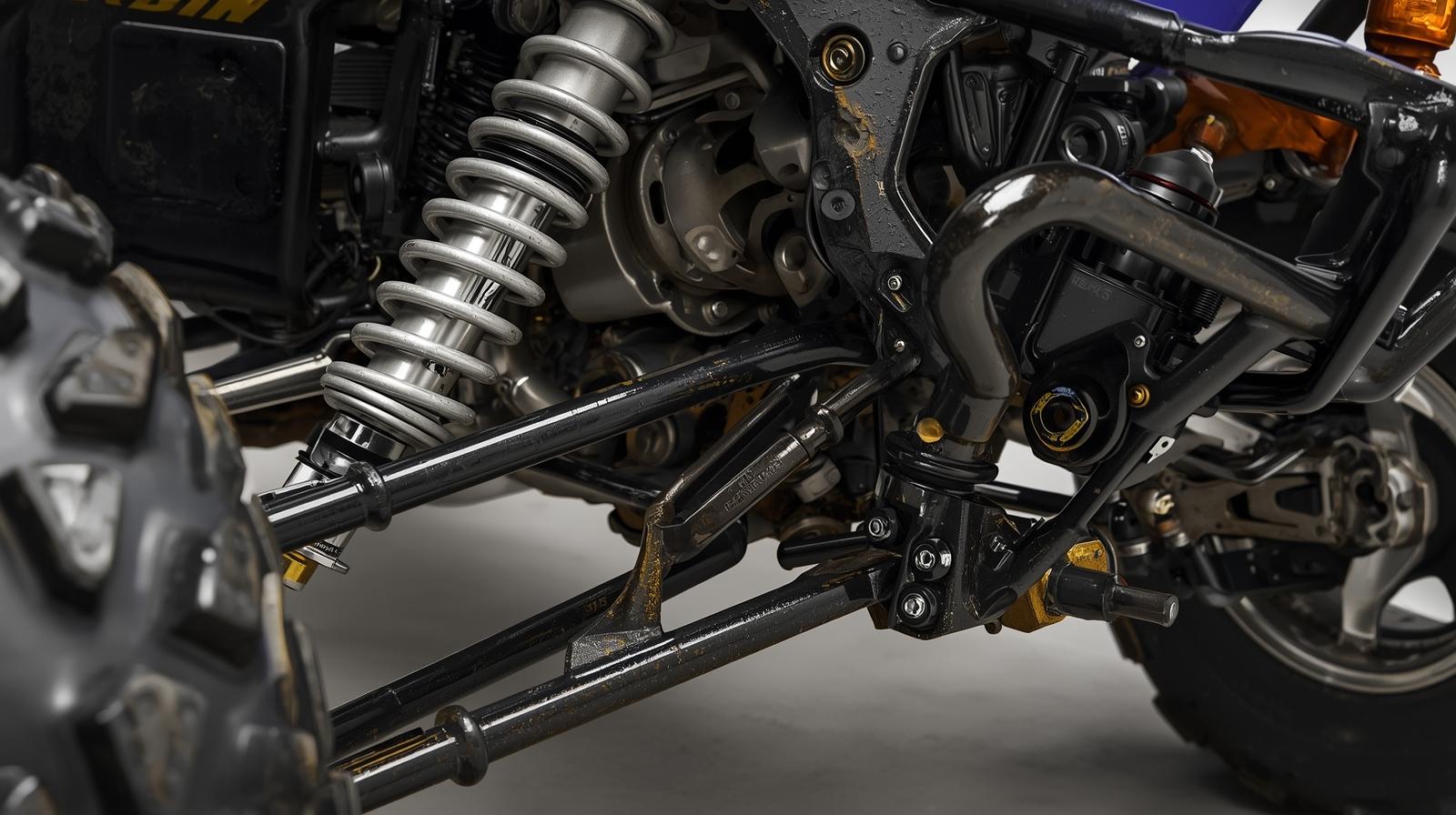

Adventure & Touring Models: Endurance-tested units certified for long-distance vibration cycles.

-

Performance & Racing: Custom damping profiles produced under monitored CNC and nitrogen-fill control.

-

Electric Motorcycles: Lightweight aluminum assemblies verified for torque consistency and low energy loss.

Across these categories, audited manufacturing ensures that design intent translates into road performance — ride after ride, batch after batch.

Selecting the Right Audited Partner

| Evaluation Point | What Buyers Should Confirm |

|---|---|

| Certification Validity | Check audit date & issuing body (SGS, TÜV, BV) |

| Product Scope | Verify whether both springs & dampers are included |

| Testing Transparency | Request damping curve and salt-spray results |

| Communication | Direct engineer-to-buyer interface, not trading intermediary |

| Continuous Audits | Ensure annual re-validation, not one-time inspection |

An audited partner provides measurable reliability, not promises.

Common Buyer Questions

Q1: How often must factories renew their audit?

Most international audits remain valid for 12 months and require re-inspection before renewal.

Q2: Does auditing increase cost?

Marginally — about 2 % – 3 % per unit — but it prevents costly recalls or inconsistent batches later.

Q3: Can smaller MOQs still qualify for audited production?

Yes. Verified factories often support pilot runs of 100 – 200 sets under the same QC standards.

Q4: Which audit bodies are globally recognized?

SGS, Bureau Veritas, TÜV SÜD, and Intertek are among the most accepted by OEM buyers worldwide.

Trust Built Through Verification

An audit doesn’t replace engineering — it confirms it.

In the global motorcycle supply chain, transparency has become as valuable as torque strength or damping precision.

Working with an audited motorcycle suspension parts maker means gaining predictability: every unit traceable, every tolerance measurable, every document verifiable.

To explore certified suspension solutions and verified production capabilities, visit our homepage or contact our technical team here.