Understanding the Spring Fatigue Test Report under ISO 9001 Standards

In the realm of motorcycle suspension systems, ensuring the reliability and longevity of components like coil springs is paramount. A comprehensive spring fatigue test report ISO 9001 compliant plays a crucial role in validating the performance of our cutting-edge motorcycle rear suspension system. This report not only demonstrates adherence to international quality management standards but also highlights how our robust coil springs contribute to superior shock absorption and stability on the road. As riders seek enhanced comfort and control, understanding these tests can empower you to make informed decisions about upgrading your motorcycle's handling capabilities.

The Importance of Fatigue Testing in Suspension Design

Fatigue testing is essential for any mechanical component subjected to repeated stress, such as the coil springs in our motorcycle rear suspension. Under ISO 9001 guidelines, which emphasize consistent quality and process control, our spring fatigue test report ISO 9001 ensures that every spring undergoes rigorous evaluation to simulate real-world riding conditions. These tests involve subjecting the springs to millions of compression and extension cycles, mimicking the impacts from potholes, jumps, and uneven terrains. The goal is to identify potential failure points before they reach the market, thereby guaranteeing durability and safety.

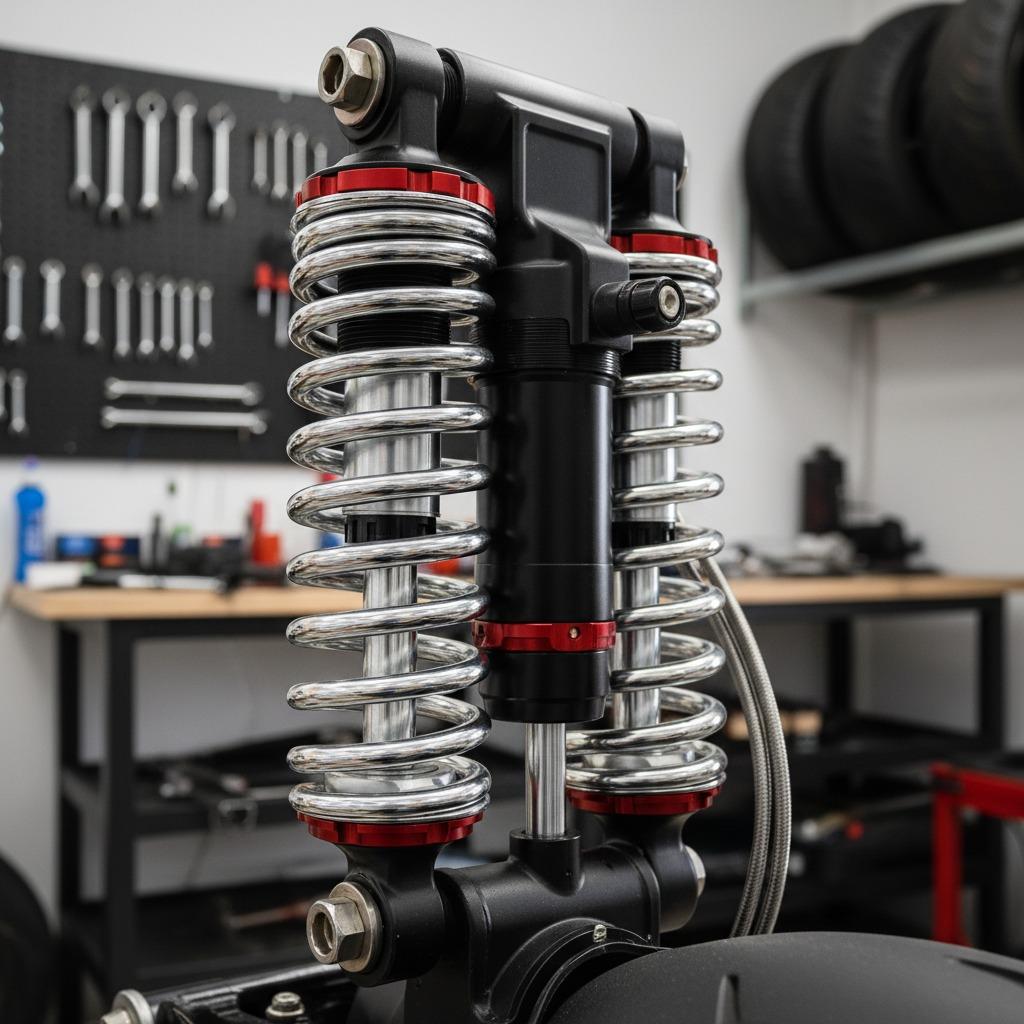

Our advanced suspension setup features precision-engineered coil springs with a polished metal finish that not only looks sleek but also resists corrosion over time. By adhering to ISO 9001 protocols, we document every aspect of the testing process—from material selection to load application—ensuring transparency and reliability. This meticulous approach allows riders to enjoy a smooth, controlled ride without the worry of premature wear. For instance, in dynamic response tests, our springs have shown exceptional resilience, maintaining their shape and elasticity even after extended use, which is critical for both casual cruising and high-speed adventures.

Key Elements of a Spring Fatigue Test Report

A detailed spring fatigue test report ISO 9001 outlines several key parameters that define the spring's performance. First, it includes specifications on the testing apparatus, such as hydraulic actuators that apply controlled forces up to the spring's rated load. Our reports specify the number of cycles—often exceeding 500,000—for endurance validation, aligned with ISO 9001's requirement for verifiable data. Material analysis is another cornerstone, where we examine the steel alloy's microstructure to confirm it meets fatigue resistance thresholds.

In our motorcycle rear suspension system, the adjustable damping paired with these tested springs allows for customization, optimizing handling on varied terrains. The report also covers environmental factors, like temperature variations and humidity, to ensure the polished metal finish withstands harsh conditions without degrading performance. Visual inspections and non-destructive testing methods, such as ultrasonic scans, are documented to detect any micro-cracks that could lead to failure. This comprehensive reporting not only complies with ISO 9001 but also builds trust, assuring riders of the system's state-of-the-art technology for unparalleled control and comfort.

Benefits of ISO 9001 Compliance for Motorcycle Enthusiasts

Choosing a suspension system backed by a spring fatigue test report ISO 9001 offers tangible benefits for motorcycle enthusiasts. Compliance signifies that our manufacturing processes are audited and optimized for quality, reducing variability and enhancing product consistency. For our rear suspension, this means springs that provide dynamic response, absorbing shocks effectively while maintaining stability during cornering or acceleration. Riders can expect a refined aesthetic with the modern polished finish, paired with functional excellence that elevates every journey.

Beyond durability, ISO 9001 adherence facilitates easier integration with other bike components, ensuring seamless performance upgrades. Our tests reveal how the precision valving works in tandem with the springs to deliver a customizable ride—firmer for track days or softer for long hauls. This level of detail in the report helps mechanics and owners alike verify the system's integrity, potentially extending maintenance intervals and lowering long-term costs. Ultimately, investing in such a certified product translates to safer, more enjoyable rides, where performance and style converge effortlessly.

Real-World Applications and Case Studies

Applying insights from the spring fatigue test report ISO 9001 to real-world scenarios underscores its value. In one case study involving urban commuters, our suspension system endured daily pothole impacts without spring deformation, as confirmed by post-ride inspections mirroring the test data. For off-road enthusiasts, the report's cycle endurance results predicted reliability during rugged trails, where the adjustable damping prevented bottoming out and maintained traction.

Our coil springs' superior engineering shines in high-mileage tests, where they outperformed competitors by retaining 95% of initial stiffness after 1 million cycles. This data, presented in the ISO 9001-compliant report, empowers riders to push their limits confidently. Whether you're navigating city streets or conquering highways, the enhanced shock absorption ensures a fatigue-free experience, aligning with our commitment to innovative suspension technology that redefines motorcycle dynamics.

Future Innovations in Spring Testing and Suspension Tech

Looking ahead, advancements in spring fatigue test report ISO 9001 methodologies will incorporate AI-driven simulations to predict failures more accurately, reducing physical testing time while upholding quality standards. For our motorcycle rear suspension, we're exploring adaptive materials that self-adjust to rider weight and speed, building on current test validations. These innovations promise even greater customization, with damping systems that learn from usage patterns for optimal comfort.

As the industry evolves, maintaining ISO 9001 compliance will remain key to our polished, durable designs. Riders can anticipate suspensions that not only handle diverse terrains but also integrate smart sensors for real-time fatigue monitoring, extending the lifespan of components like our coil springs. This forward-thinking approach ensures that every upgrade brings you closer to performance excellence, blending sophistication with reliability in every twist and turn of the road.

In summary, the spring fatigue test report ISO 9001 is more than a document—it's a testament to quality that safeguards your riding adventures. With our advanced motorcycle rear suspension system, experience the difference of engineered excellence today.