Quick-Response Spring Tech Support: Fast Solutions for Complex Suspension Needs

When Delays Cost More Than Time

In suspension manufacturing, a production delay isn’t just inconvenient — it can disrupt entire supply chains. A shipment halted for spring fitment issues or load inconsistencies may cause downtime for assembly lines and distribution partners alike.

That’s why quick-response technical support has become a cornerstone of modern suspension supply. Rather than waiting days for feedback, OEM clients now rely on specialists who can analyze test data, propose adjustments, and confirm material compatibility within hours, not weeks.

Inside Rapid Spring Troubleshooting

Quick-response service is built on three interconnected pillars — diagnostics, communication, and re-engineering.

-

Real-Time Diagnostics:

Using fatigue-test data and CAD simulation, technicians identify the source of a load imbalance or rebound variance quickly. -

Direct Communication:

Instead of multiple layers of intermediaries, engineers communicate directly with buyers and quality teams, allowing rapid corrective action. -

Re-Engineering Capability:

CNC spring winding systems can adjust pitch or wire diameter instantly, enabling rapid prototypes without halting mainline production.

Together, these processes turn what could be a week-long disruption into a same-day recovery.

Why Fast Tech Support Creates Measurable Value

| Benefit | Traditional Support | Quick-Response Model |

|---|---|---|

| Feedback Cycle | 3–5 days | 4–8 hours |

| Fitment Accuracy | Reactive adjustment | Predictive verification |

| Material Adjustment | Batch replacement | Controlled tuning |

| Communication Flow | Multi-tiered | Direct engineer-to-client |

| Downtime Impact | Extended | Minimal |

For OEM buyers managing multiple vehicle platforms, this responsiveness ensures steady assembly output and eliminates costly shipping reschedules.

Applications That Rely on Immediate Support

-

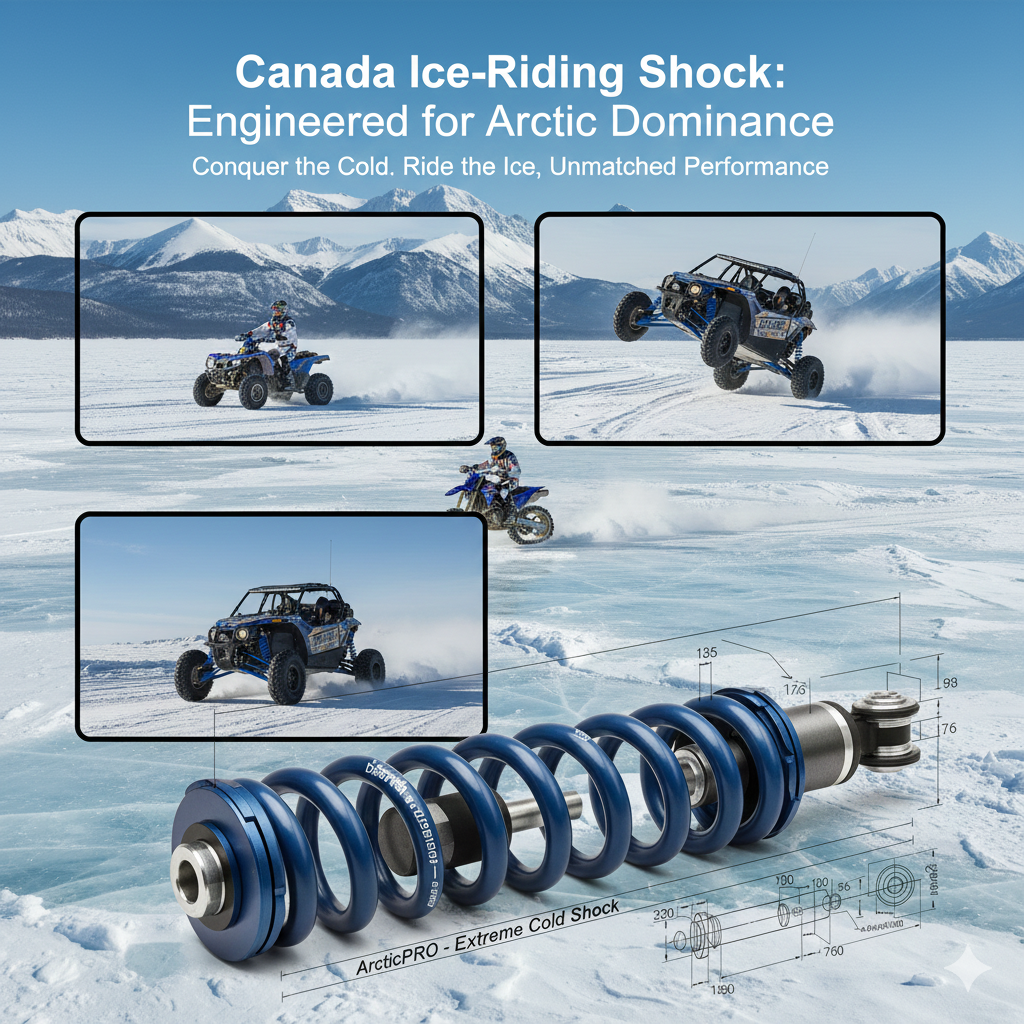

ATV & Buggy Production Lines: On-site spring recalibration minimizes delay during seasonal ramp-ups.

-

Motorcycle OEM Programs: Quick spring rate adjustment helps maintain rider comfort targets.

-

Utility Vehicle Fleets: Continuous maintenance guidance keeps suspension systems reliable under daily load.

-

Aftermarket Distributors: Rapid technical clarification prevents product returns and compatibility disputes.

In each case, fast technical feedback translates directly into cost savings and sustained customer trust.

Practical Advice for OEM & Distributor Teams

To make the most of responsive support:

-

Keep test data logs accessible — force curves, wire specs, and mounting details speed up troubleshooting.

-

Use standardized feedback templates when reporting fitment or damping issues.

-

Select suppliers with in-house engineering teams, not outsourced service desks.

-

Ask for digital prototype approval (3D simulation or virtual fit test) before production change.

A structured communication loop reduces misunderstandings and prevents repeated design iterations.

Buyer Q&A: How Quick-Response Support Works in Practice

Q1: How fast can adjustments be implemented?

In most cases, prototype recalibration or design correction can be issued within 24 hours after receiving data feedback.

Q2: What communication channels are used?

Support teams operate through direct engineer chats, shared dashboards, and real-time test uploads — minimizing translation delays.

Q3: Is there a minimum order size for technical service?

No. Even sample or pilot runs are supported, ensuring that performance validation happens before scaling.

Q4: How does Bedo ensure accuracy in remote support?

By combining fatigue testing with CAD model validation, ensuring that every modification is backed by verified measurement data rather than assumption.

Why Quick-Response Support Reflects True Partnership

Fast service is not just about answering quickly — it’s about understanding context. When technicians already know a client’s product line, every response is proactive rather than reactive.

At Bedo, decades of OEM experience allow our team to provide same-day analysis, model-specific tuning, and verified re-engineering for coil springs and shock systems.

Our goal is to ensure every suspension project — from prototype to shipment — runs without disruption.

Learn more about our global technical support and product lines on our homepage or contact our specialists directly via contact page.